On Friday, August 2, Eco-Ambassadors visited Jordan Dairy Farms Heifer Facility in Spencer, MA to learn about organics to energy anaerobic digestion. Jordan Dairy Farms partners with Vanguard Renewables, a company that engineers and operates anaerobic digesters, to repurpose food waste and manure as bedding and fertilizer. The trip demonstrated how closing the waste cycle can be cost effective and energy efficient.

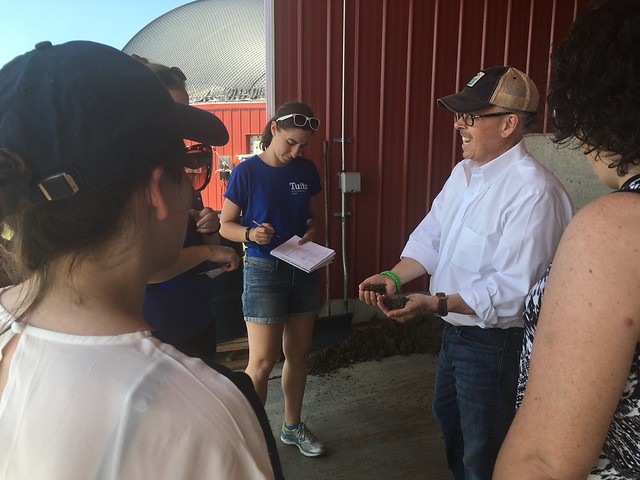

Inputs: Vanguard Renewables’ food industry customers, including manufacturers, breweries, and grocery stores, send their depackaged food waste to Jordan Dairy Farms. The farm receives about 120 tons of food waste each day, between five and ten truckloads. The food waste is added to the first anaerobic digester, along with manure produced by the farm’s cows.

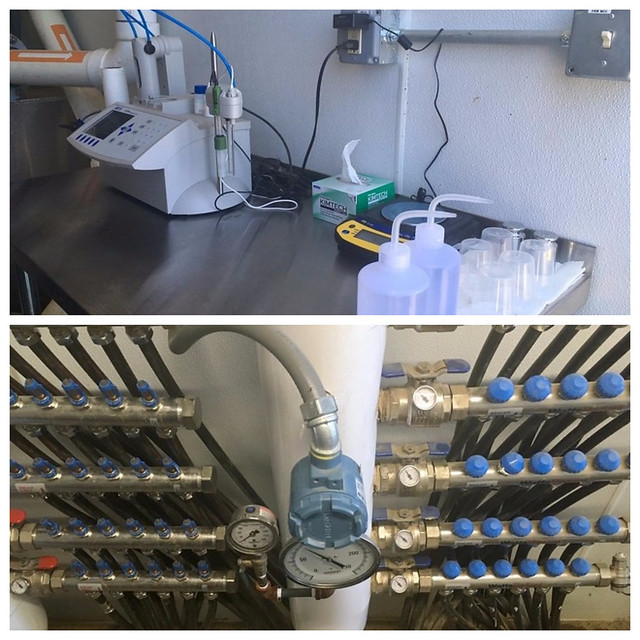

What Happens: Incoming organic waste is filtered for plastic and other solid contaminants, then mixed with waste already inside the first digester. The methanogens, or digesting bacteria, can only survive a 0.5 degree temperature change in a period of 12 hours, so convection keeps the mixture at a steady 104 degrees. Waste air passes through three successive filters– cedar chips, activated carbon, and carbon– to eliminate odors.

Below: Pressurized tubes control digester heating and cooling.

After five days in the first digester, the mixture is transferred to the second digester, where it will spend 25 days. The organic waste is mixed at various heights throughout the digester to ensure uniform temperature and pH. 200 different sensors monitor the digester at all times. The biogas produced in the second digester is about 65% methane, with some carbon dioxide and hydrogen sulfide. The gas is captured in two membranes stretched above the digester.

Outputs: The gas is sent to a combustion engine connected to a generator, producing one megawatt of power every hour. The liquid is extracted from the digested waste and becomes organic fertilizer for crops, while the leftover solids become soft, dry bedding for cows. As part of their partnership, Vanguard Renewables shares all digestion products with Jordan Dairy Farms.

Vanguard Renewables operates five anaerobic digesters on small, family dairy farms across Massachusetts, and receives food waste from 65% of Massachusetts food manufacturers. Anaerobic digestion diverts organic waste from the landfill and reduces greenhouse gas emissions from said waste by more than 85%. Anaerobic digestion shows that renewable technologies both protect the environment and stimulate the economy.

Leave a Reply