Printer Number 1 in NOLOP was used for every version of this assignment. I decided to print out a component of the chair I created for the CAD assignment (the stool portion).

Monday 10/10/22

Setting Up the Print:

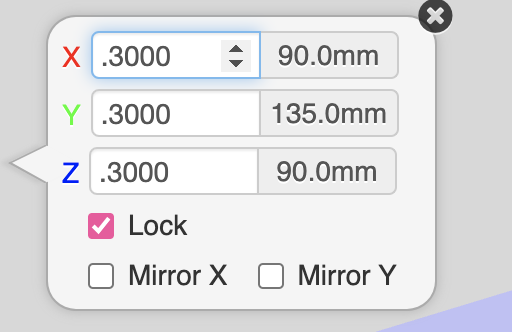

This step involved finding a printer that was open for use. I decided to use NOLOP printer 1 which is located on the top left of the shelf out of all 12. Initially, the sizing of the object was an issue so the dimensions needed to be changed. I was able to scale down the stool to 0.3, which equates to 90 mm in the x direction, 135 mm in the y direction, and 90 mm in the z direction. This is also depicted in Figure 1 below, where the scale is locked so that the dimensions adjusted automatically.

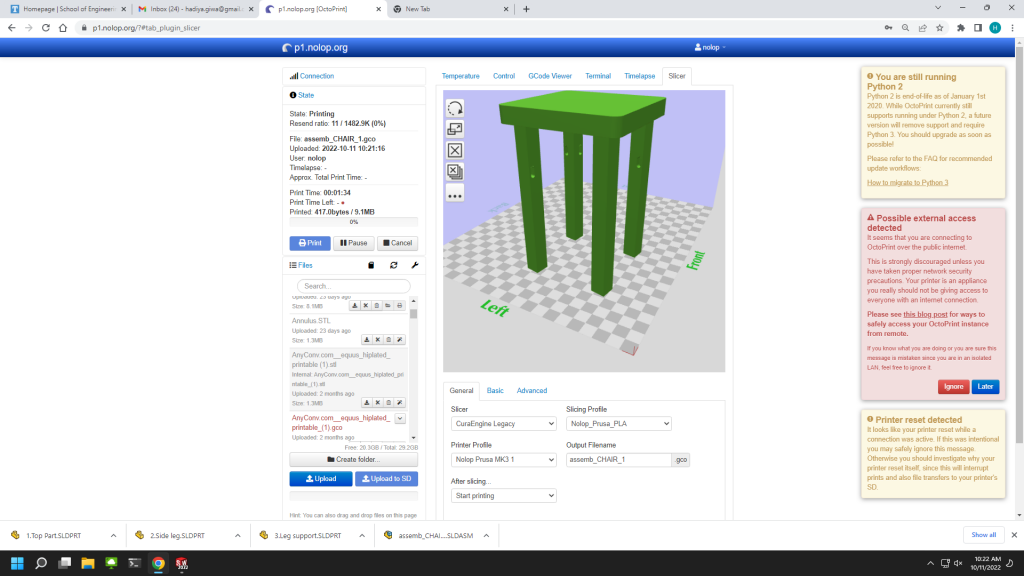

The next step involved adjusting the orientation of the stool on the 3D printing plate. Initially it was lying on its side, which would have caused multiple issues during the actual print. The object had to be rotated 90 degrees so that it could stand on all four legs of the chair. This is depicted by Figure 2 below. In addition, supports were added in the advanced features under settings.

After the initial set up, the machine was ready to begin. Or so I thought.

Print 1: Failed Attempt

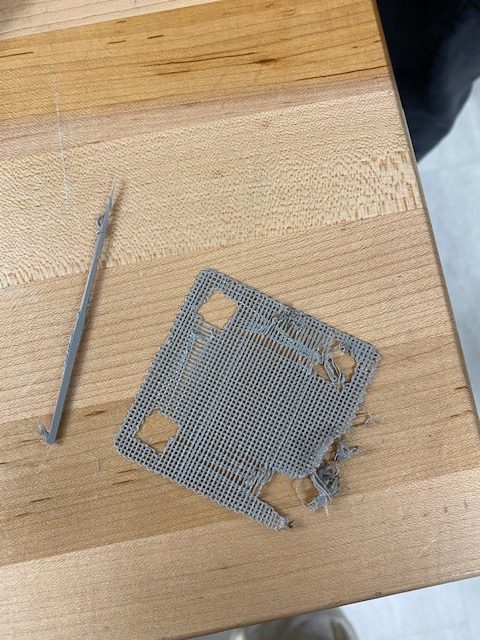

Multiple issues arose before an actual successful print. The first being that the adhesion of the plate was poor and hair spray should have been sprayed on the surface first. A few minutes after the print began, it was clear that the design was not remaining in place and was sliding all over the place. This is apparent in Figure 3 below, where the initial base layer of support has been completely shifted, causing some build-up in the printer nozzle as well.

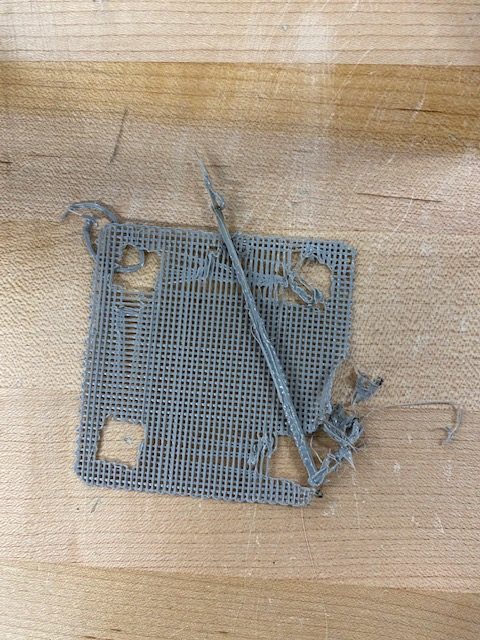

The following pictures show the failed attempt at the 3D print with the legs oriented first. The first layer of the support was printed before the entire print was canceled.

Figure 4, first profile of the failed print

Figure 5, second profile of the failed print

Tuesday 10/11/22

Print 2: Successful Attempt

The orientation of the stool with the legs printing first was clearly not appropriate for this print. The orientation was rotated 270 from the original starting position so that the bench portion would print first and less supports would be needed overall. This is depicted in Figure 6 below, where the stool is positioned as upside down.

This new orientation appeared to fix the initial issues, and the stool printed successfully over the course of a few hours. The final product can be seen below, where the stool stands upright and appears to be sturdy.

Give examples of objects difficult to fabricate with more traditional technologies

The full chair with backing would be quite difficult to fabricate with more traditional technologies, as well as intricate and small items