Our group decided to divide-and-conquer for molding and casting—I took point on 1-piece, so here is my documentation.

My journey of 1-piece casting started after getting Dunkin’ on a rainy Sunday morning. For the first time, NOLOP was completely empty, and the world was my oyster. However, I realized that it had been over a month since we learned how to mold and cast, so it would be a long morning.

I decided that I wanted to cast a pen out of polyurethane. I had a couple pens that were running unfortunately short on ink, so I thought it would look cool! I started by getting one of the small cups near the sink, and grabbed my silicone. Here is our subject:

Similarly to our 2-piece documentation, I used a 1:1 mixture of A and B Ecoflex 00-30 Pt-cured silicone, approximately 4/3 cups each. This left me with the following:

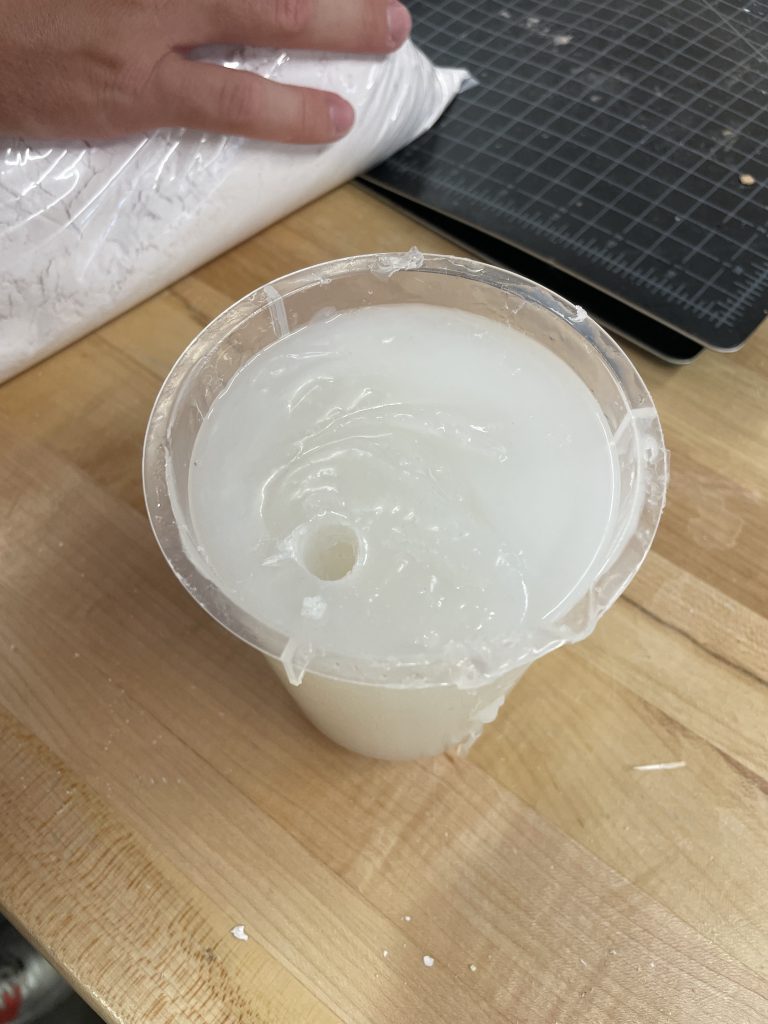

After about 24 hours, the mold was ready to be cast into:

However, there was no more polyurethane, so I had to wait until class time to finish (which is why this is being turned in late). We additionally chose to use Alja-Safe in lieu of polyurethane.

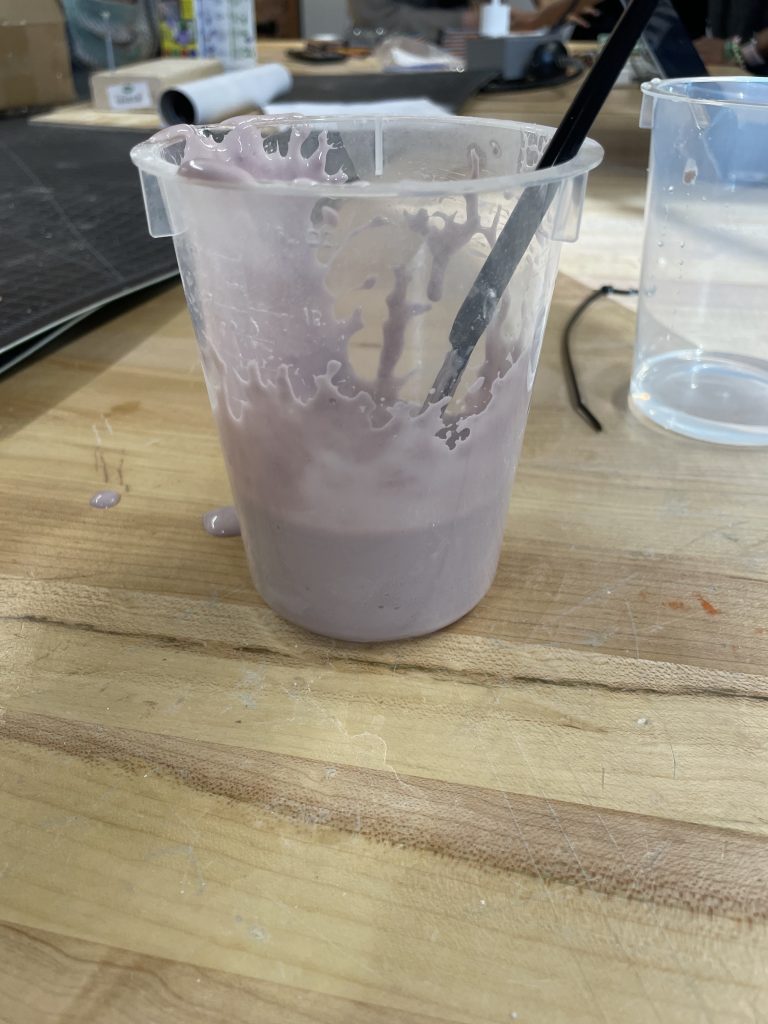

We used a 1:1 mixture of Alja-Safe and water, leaving us with this mixture:

This was cast into the mold as follows, and left to cure overnight:

In the morning, we were left with this:

To say the least, this is suboptimal. Although minor detail was captured by the cast, the final product could have been stronger. Likely, a more optimal combination of molding and casting material (the silicone and alginate didn’t play particularly well together), as well as a smaller mold (the large cup led to inconsistencies in the silicone) would have led to better results. All things to consider in future projects!

For 2-piece casting, see Justin Wang’s documentation: http://juicedtin.github.io/bme66/F5