The inspiration for this design was a new coffee cup tumbler that I had thrifted a couple weeks ago. The problem that I was facing was the lack of a handle or holder so I would always tuck the cup into my backpack, or have to hold it in my hand, and it was always a little slipery. If there was a handle, then I could just use my fingers to grab it, and would leave the rest of my hand empty and useable to carry other things!

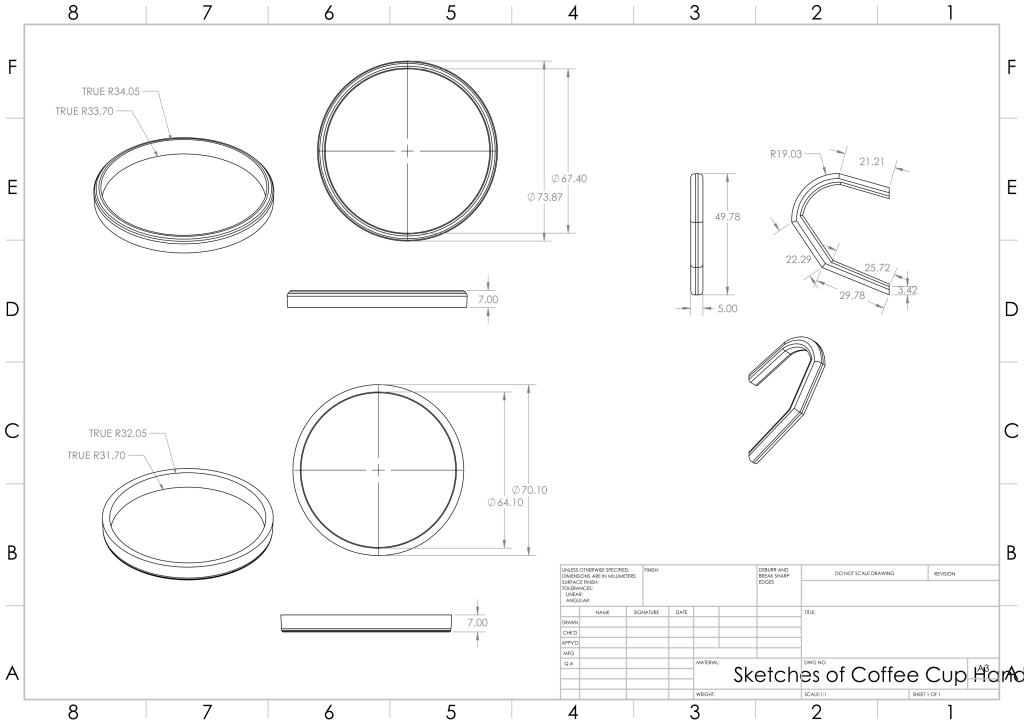

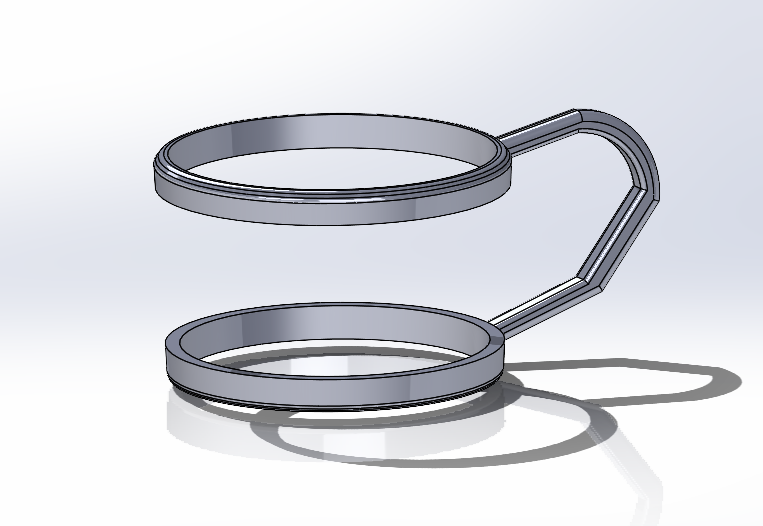

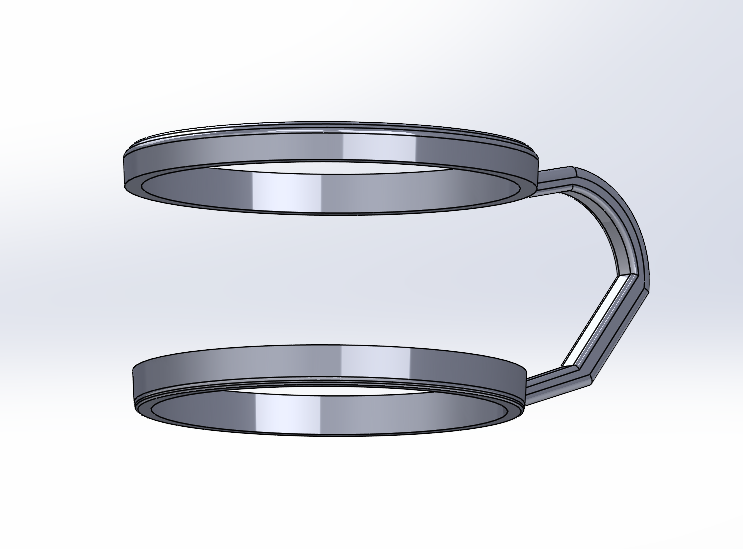

To solve this, I thought of a simple design, with two rings and a handle between it that could slip on to the cup like a coffee sleeve or a sippy cup handle. To do this, I needed three individual parts, that all worked in unison.

This design proved harder than I expected as I have had some experience with Solidworks, but not too much without some sort of direction and/or instruction. I had also not used the system in a bit so there was a bit of a re-learning curve.

After estimating the diameter of the tumbler, I started by trying to use a circle that was extruded and a hole cut in the middle, but I wanted to give the shape a bit of a curve on the inner edge so it would fit the cup better. The tumbler has a slight tapering to it, which seemed to require a different way of formation. I used the revolve feature to bring a parallelogram shape to a ring, and shaped it up a bit with the fillet/chamfer feature. Then, I copied the part and resized it to fit the dimensions of a lower ring, which is easier said than done.

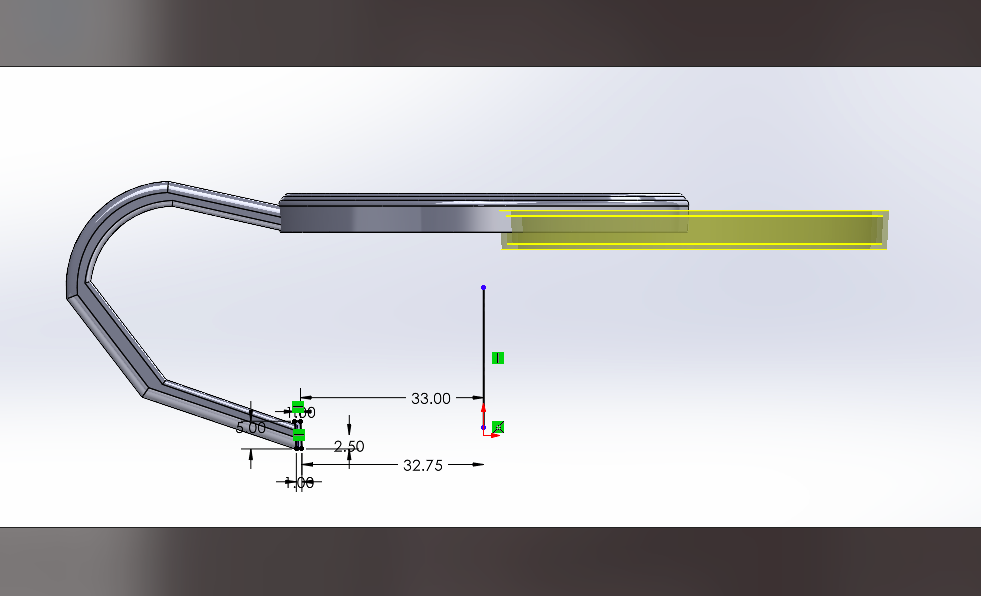

To make the handle, I looked up the dimensions of a typical coffee mug or even door handle and found that most are around a third of the diameter of the vessel, so sized accordingly (with a little bit of give just in case). This was done using a sized rectangle for reference, and lines and curves to make the shape. I then tried to revolve around this sketch, but found it near impossible, so decided to extrude and fillet instead.

To bring everything together, I opened all the pieces in an Assembly, and worked on trying to mate the correct faces with each other. This also proved more challenging that I expected because I did not realize that a round surface would be hard to mate with a flat one. I tried adding reference lines that could potentially line up with each other and mate that way, but failed to do so sucessfully.

This was one of the things I would need to learn to advance further. It is quite difficult to test devices and ensure they are properly fitted without the mates. Furthermore, I would want to work on being more proficient in knowing how to size things more accurately (as one of the elements in the handle was not fully defined, but I could not figure out where and why). I would also want to learn more on how to properly show my design on the sketches because I don’t believe that the parts are show at their best angles, and all the dimensions are not what I expected them to be.