For a final project in our Engineering Design class, we created Brake Sense, a device that taught us many engineering fabrication techniques such as molding/casting, hand drills, soldering, and more, while working towards a mission of making walkers more user-friendly and cost-efficient by reverse engineering existing walker and brake systems.

Our Goals

- Cost and Maintenance: Striving for simplicity and ease of replaceability, supported by rigorous testing protocols to ensure the reliability and excellence of our products.

- Adaptability: Made to fit various people of all shapes, sizes, and heights with varying levels of support.

- For The People: Committing to regular customer feedback sessions is a cornerstone of our commitment to continuous improvement, ensuring that our products evolve in direct response to the needs and preferences of our valued customers.

- UN Sustainable Development Goals: #10 Reduced Inequalities & #12 Responsible Consumption and Production

TEAM MEMBERS: Jolene Gianone, Faith Moran, Fua Nasu, Mahika Shrivastava, and Natasha Wan (me!)

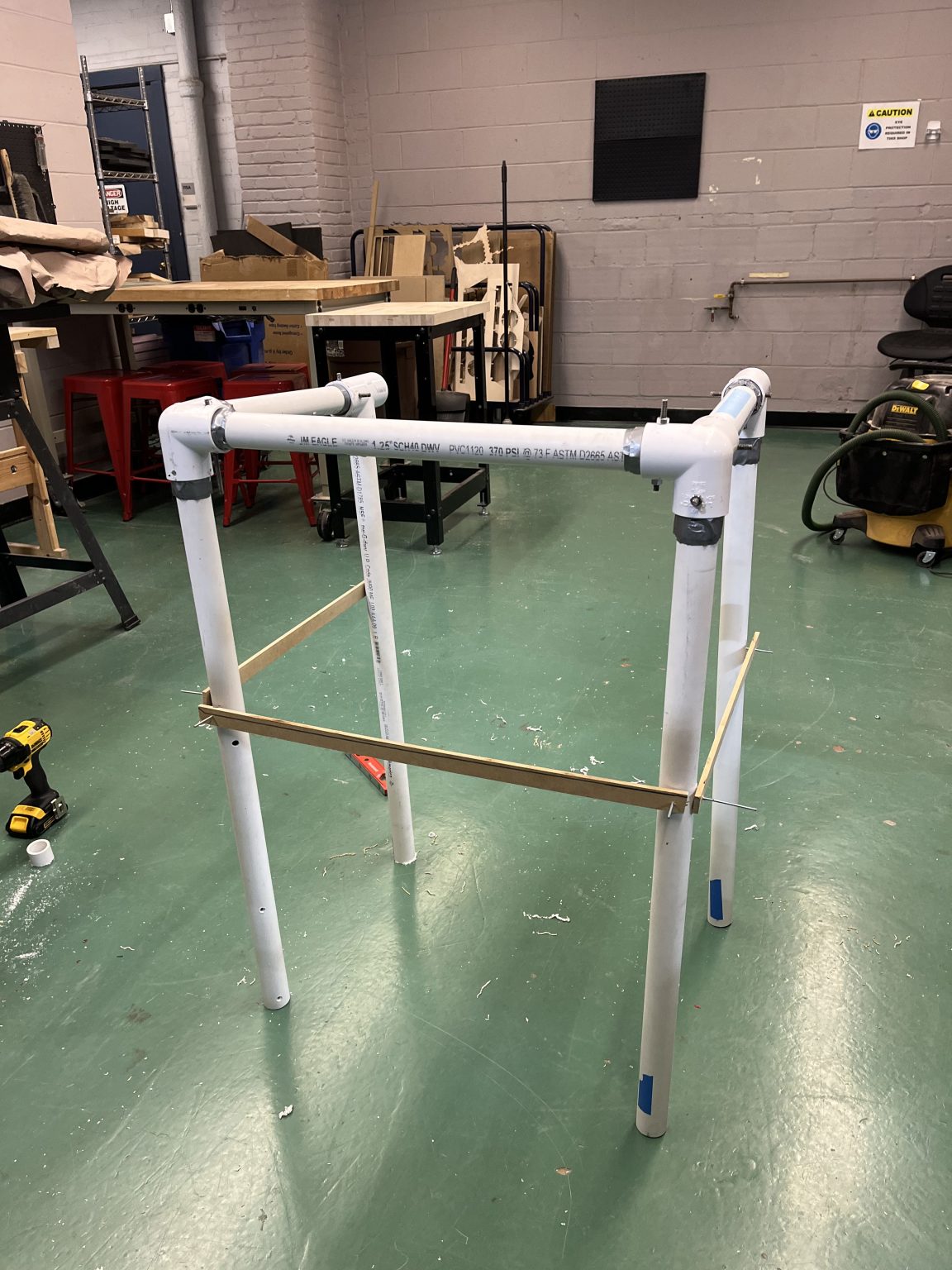

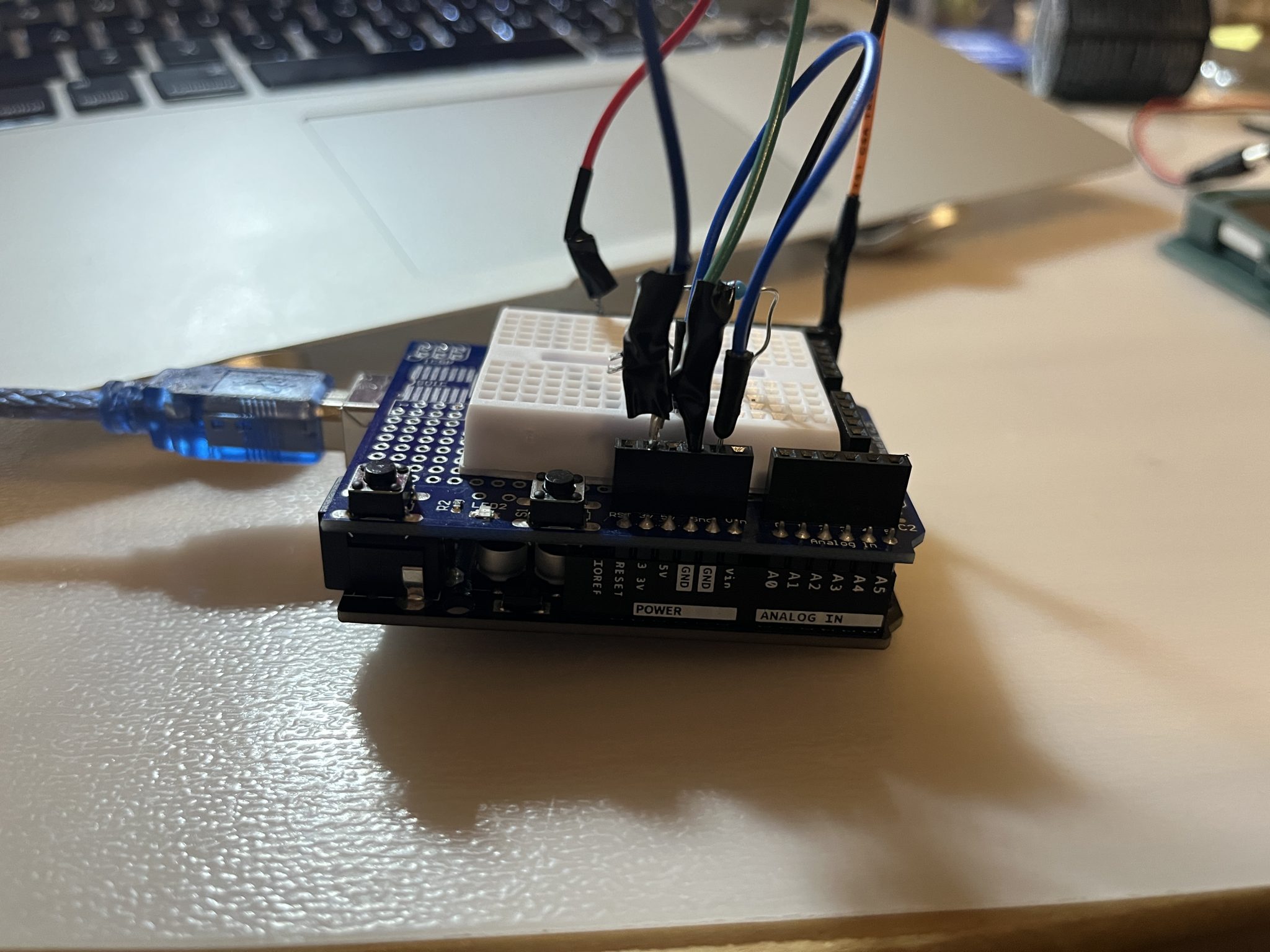

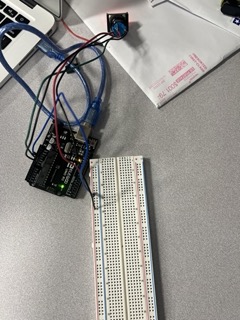

Final Prototype

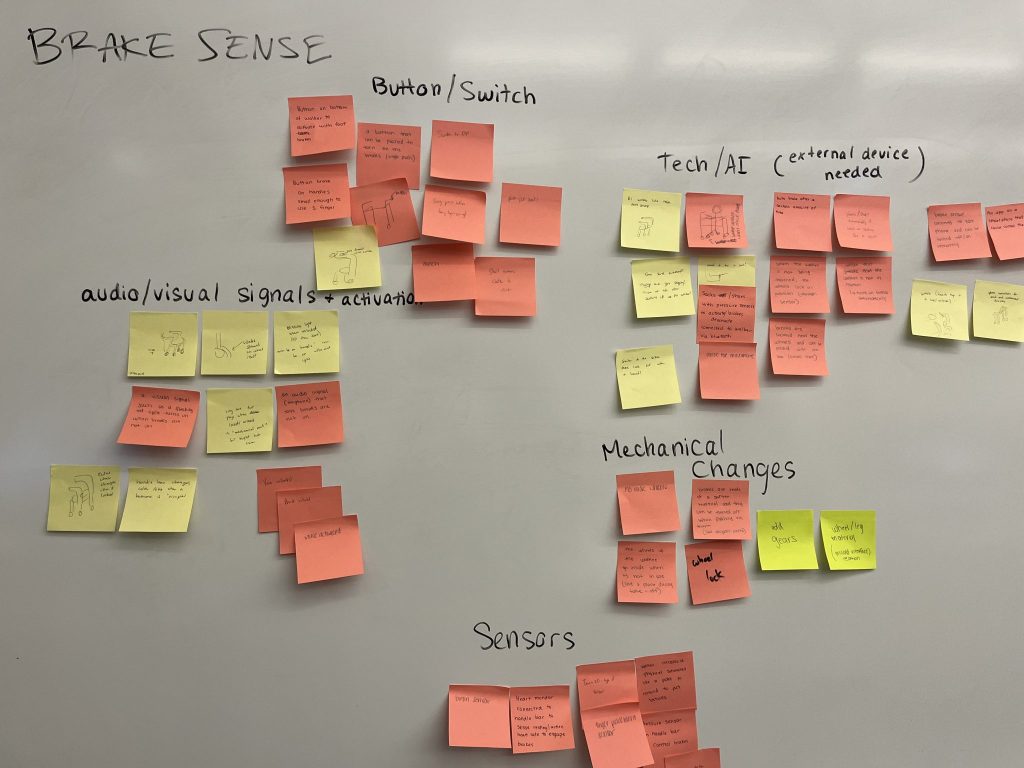

The process of this project included updating and following our needs statement, using our resources to interview for walker users and healthcare providers/family members who aid walker users. Through this research, it was found that status indication and ease/effectiveness of brake use were the top two concerns of both users and healthcare providers. Furthermore, in the process of this project, our plans changed from simply adapting an existing walker, to really understanding the “black box” components of a walker, and creating one from scratch. This new path led to a connection with my passions for accessibility in low-income, low-resource settings, and we added the UN Sustainable Development Goals to our project’s mission.

PROJECT PLAN

Gantt Chart

To plan our project, our team used a Gantt chart. This way, we could list tasks, delegate assignments, and keep track of due dates with ease. You can view our Gantt chart by clicking the following link: Gantt Chart.

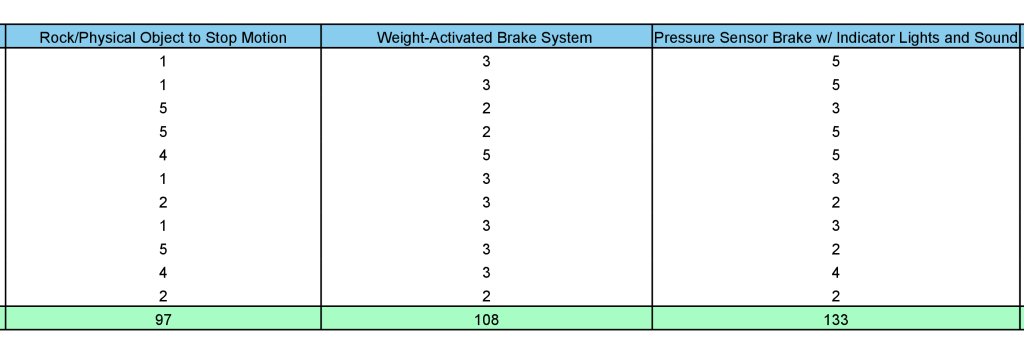

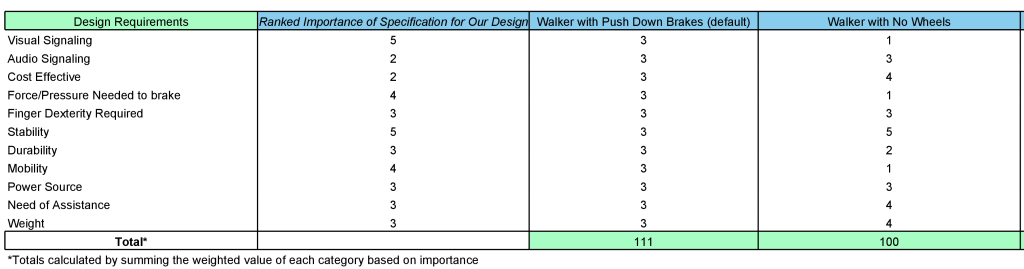

Pugh Matrix

Objective: Design an easy-to-use brake addition to an existing walker that indicates the state of the brakes.

Target Audience: Walker users

A Traceability Matrix was used to ensure this device was safe and matching the

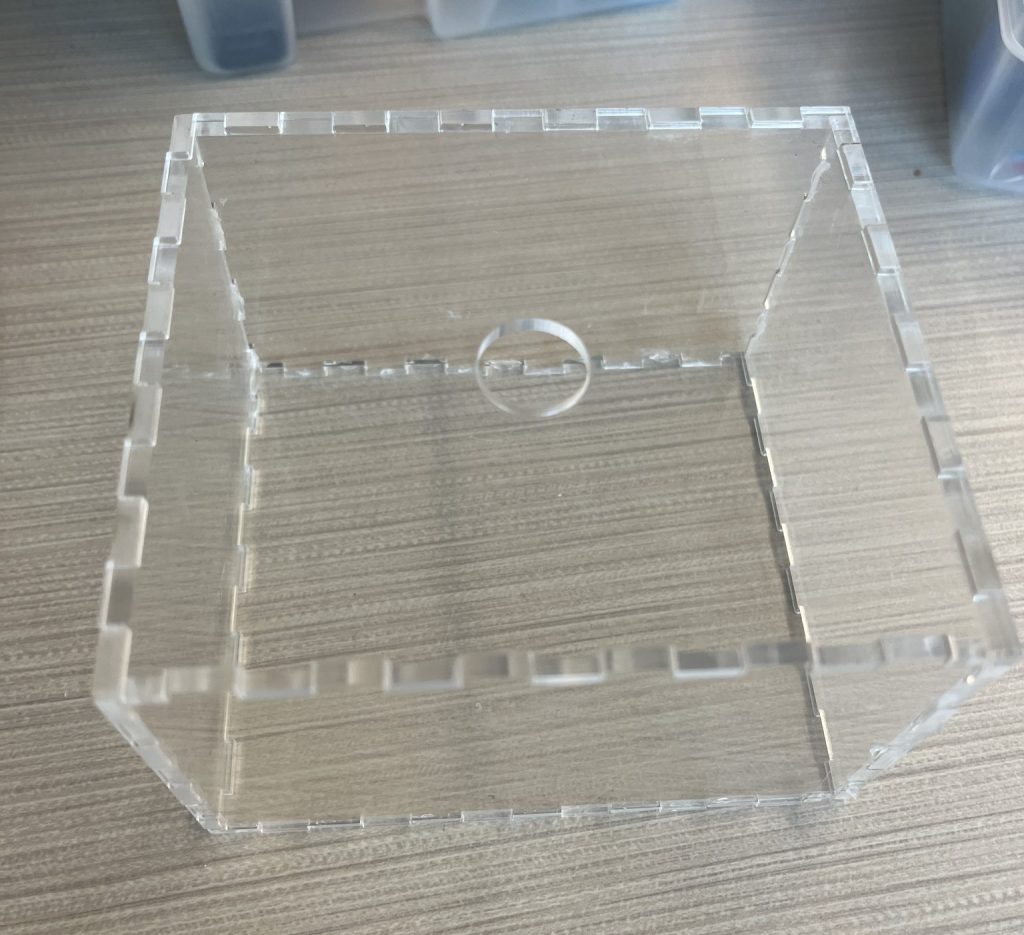

Prototype Progress

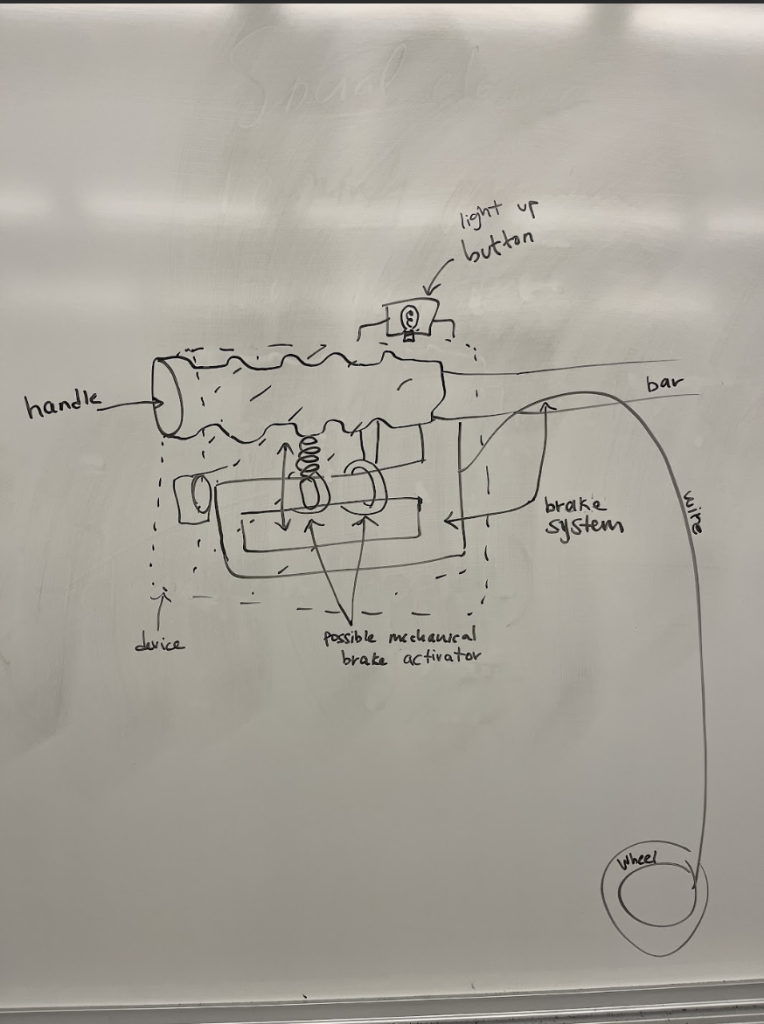

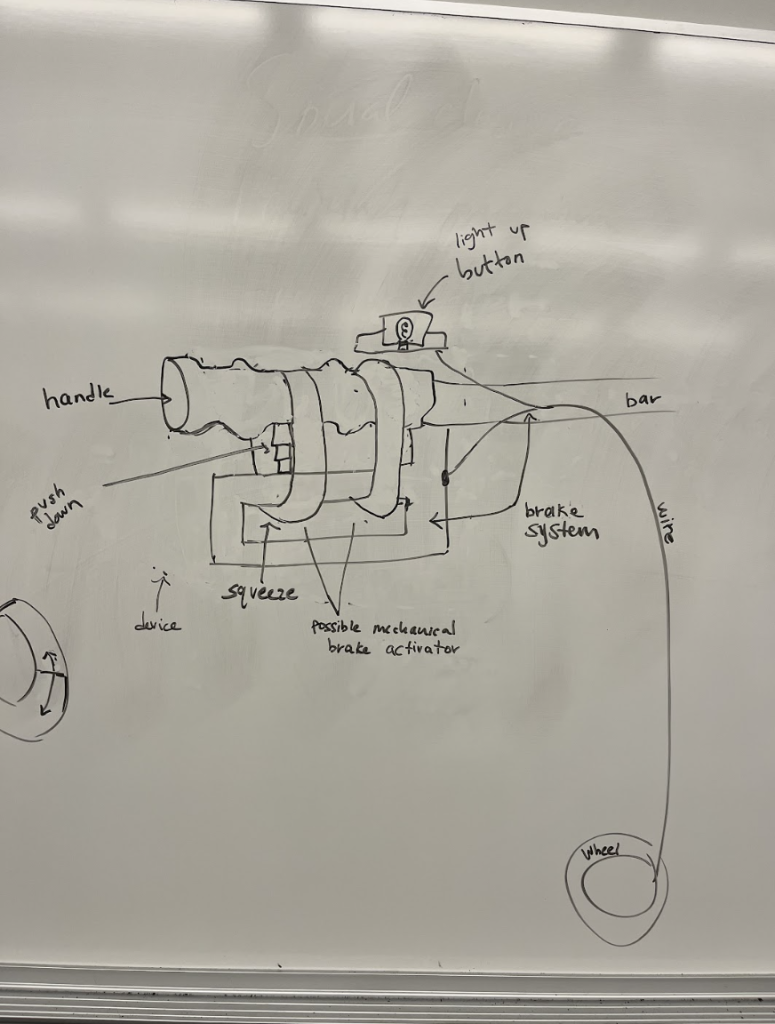

Prototype Sketches

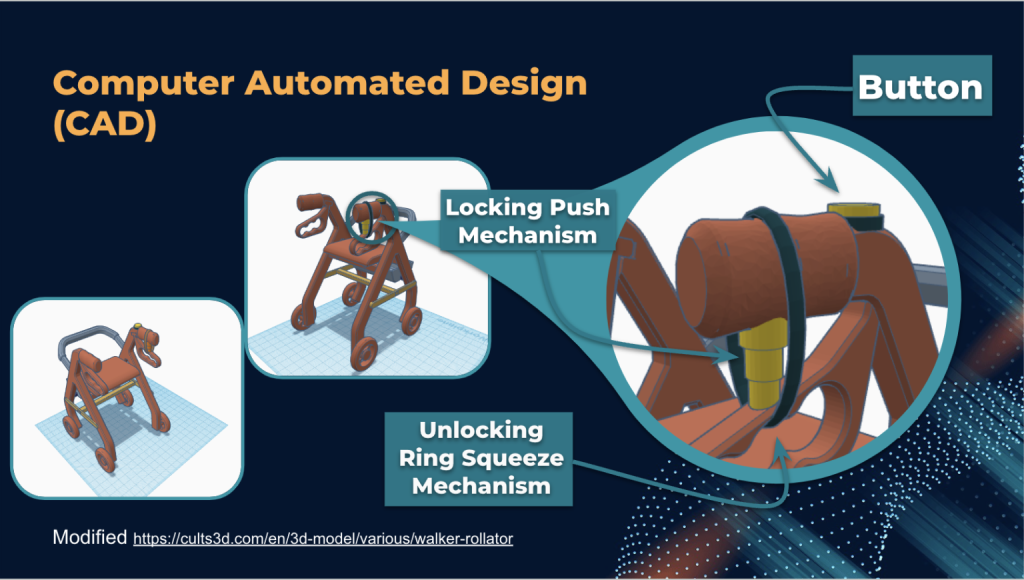

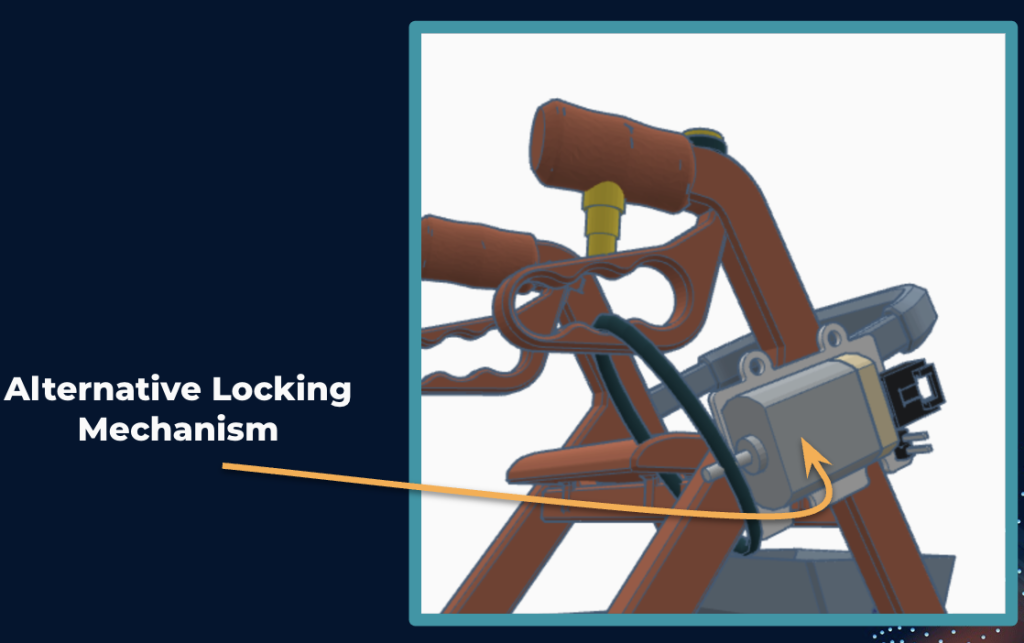

Initial and Final CAD Models

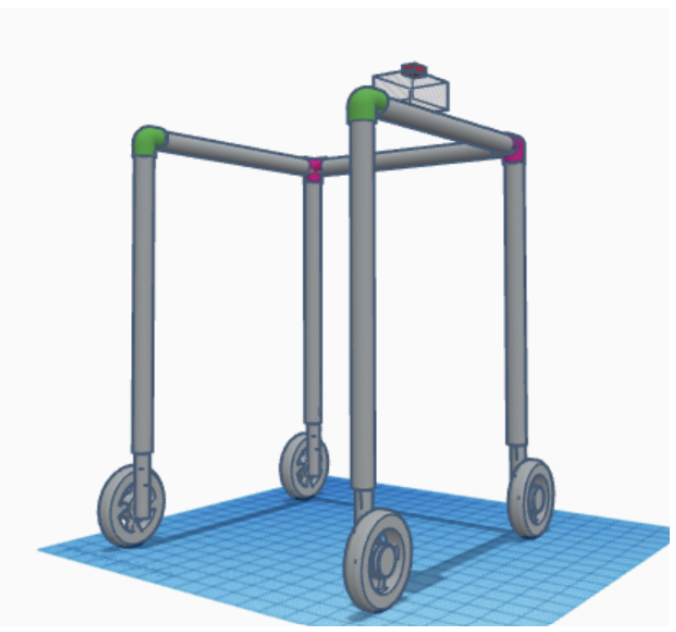

More realistic CAD model of actual fabricated prototype with PVC pipe, walker wheels, and button on top of handle

Prototype Building