At first, I didn’t really know what I wanted to create since I am still a beginner at CAD and SolidWorks so I went with an easy design and one that might have some applications to what I wanted to do ….. so I chose a stent. 🙂

I mean sure, there are more challenging stent designs out there (that I might take a stab at, but since it’s my first time, I decided to go with a simple shape and design.

Software: SolidWorks | Units: MMGS millimeters/grams/seconds

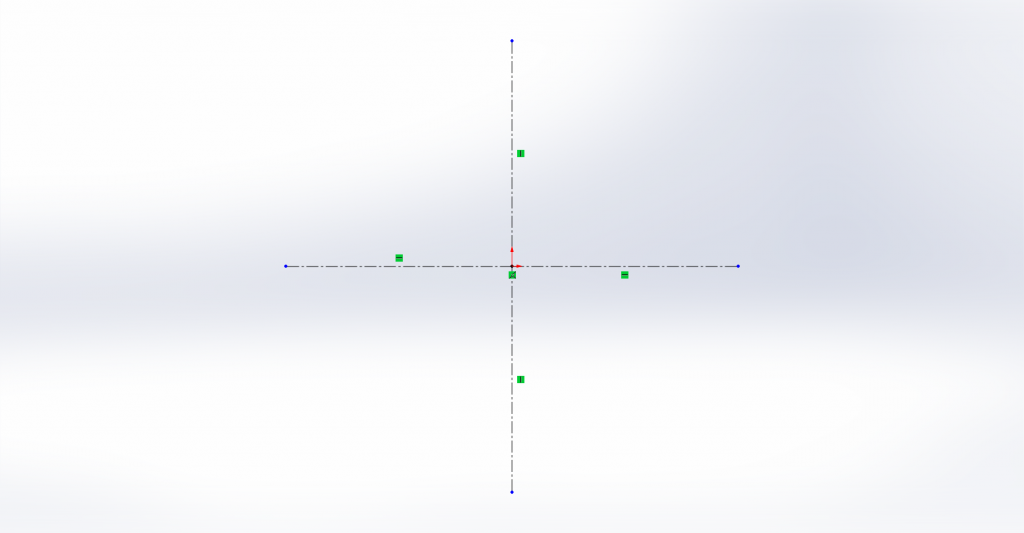

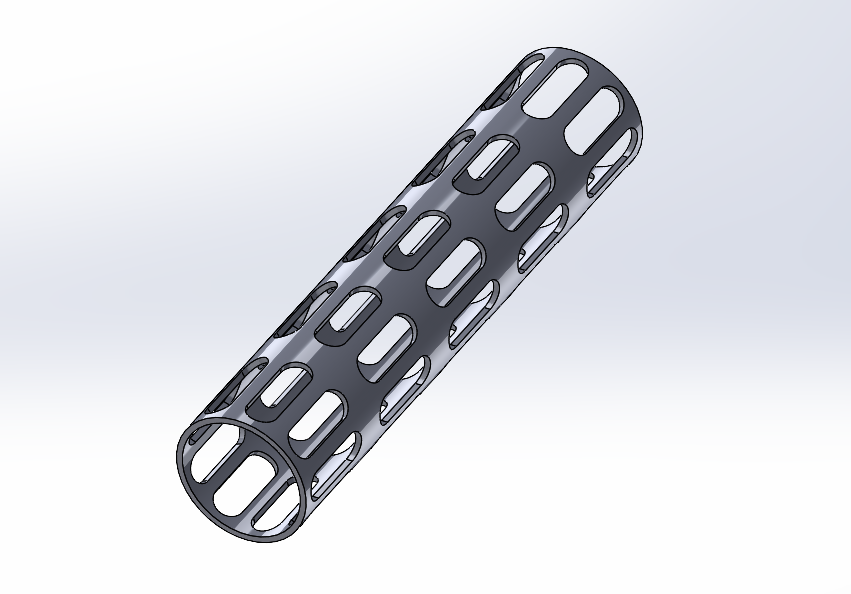

First I created gridlines that measured about 100 mm (millimeters) vertically and horizontally using the centerline function and then created a circle with a radius that measured about 10 mm (millimeters) in the origin.

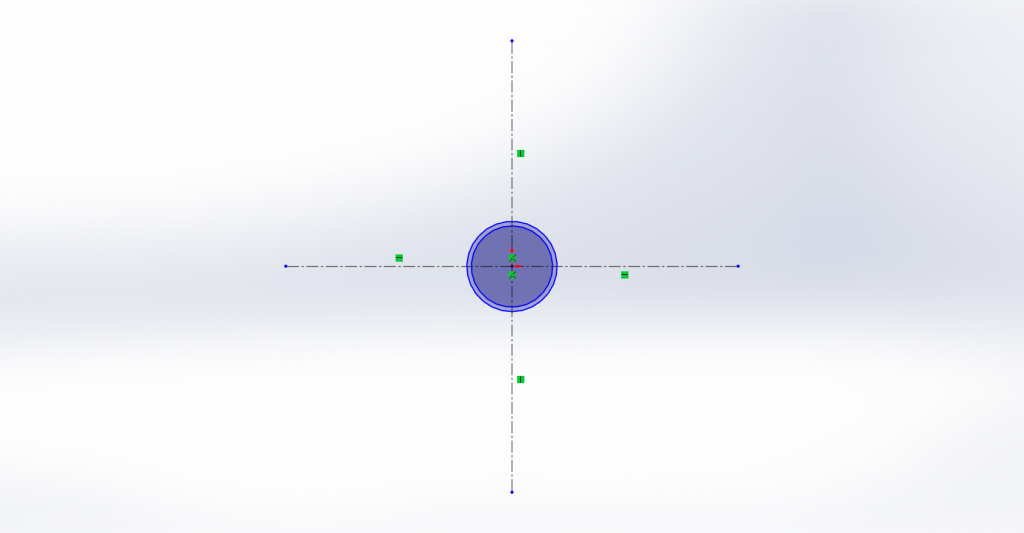

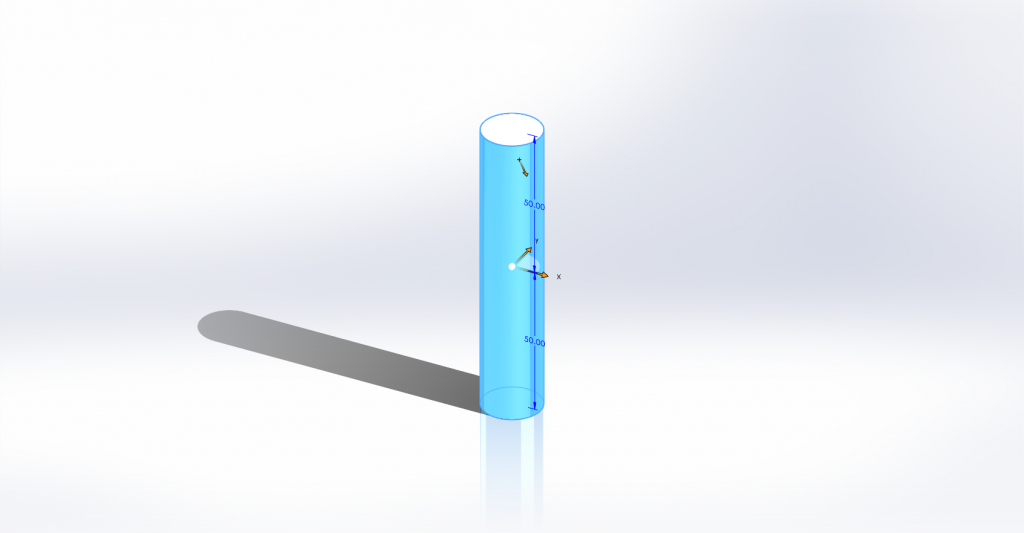

After creating the circle, I then used the ‘offset entities” function in order to create a smaller circle inside the original circle that has a radius of about 9 mm which created a shell that was 1 mm thick. I then “extruded” the circle to create a cylinder that was 100 mm long.

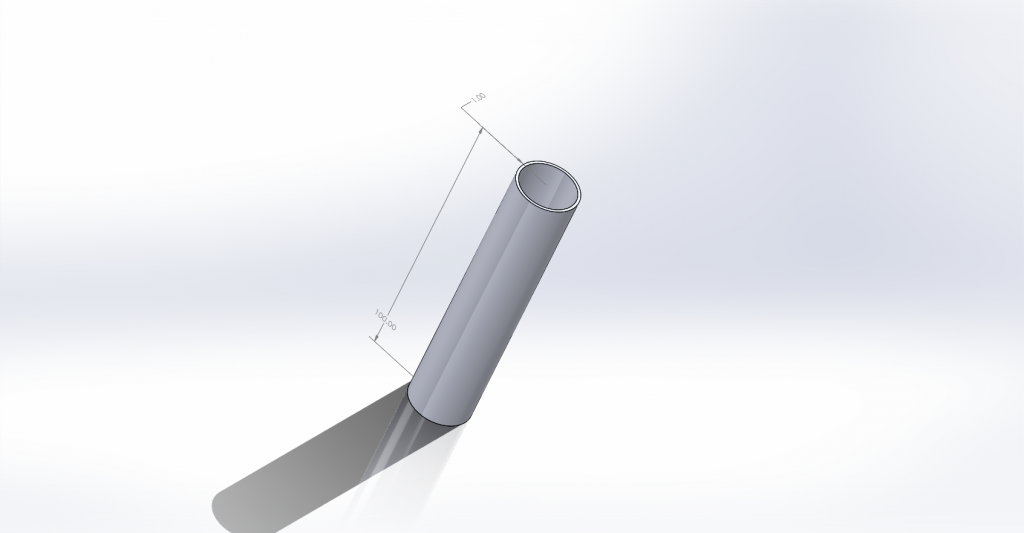

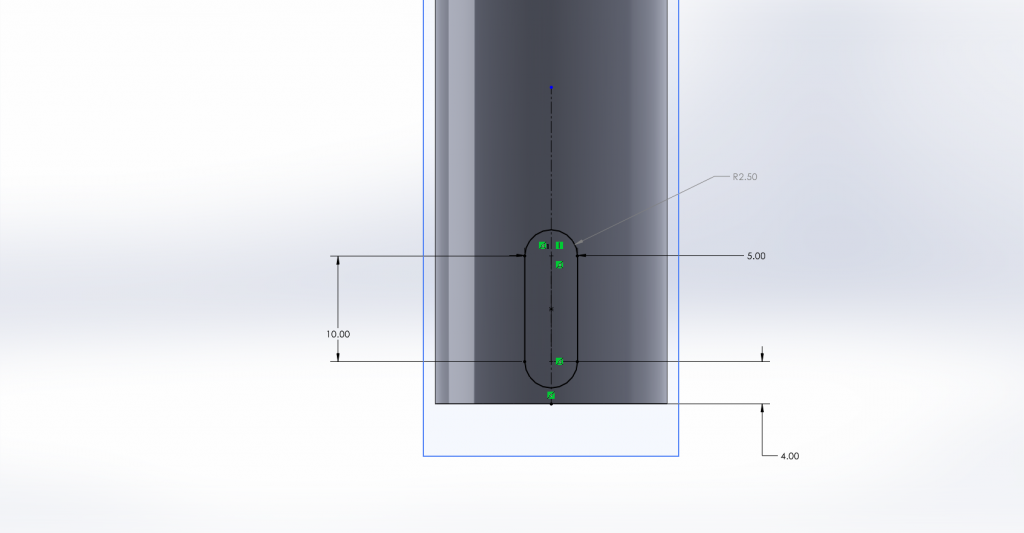

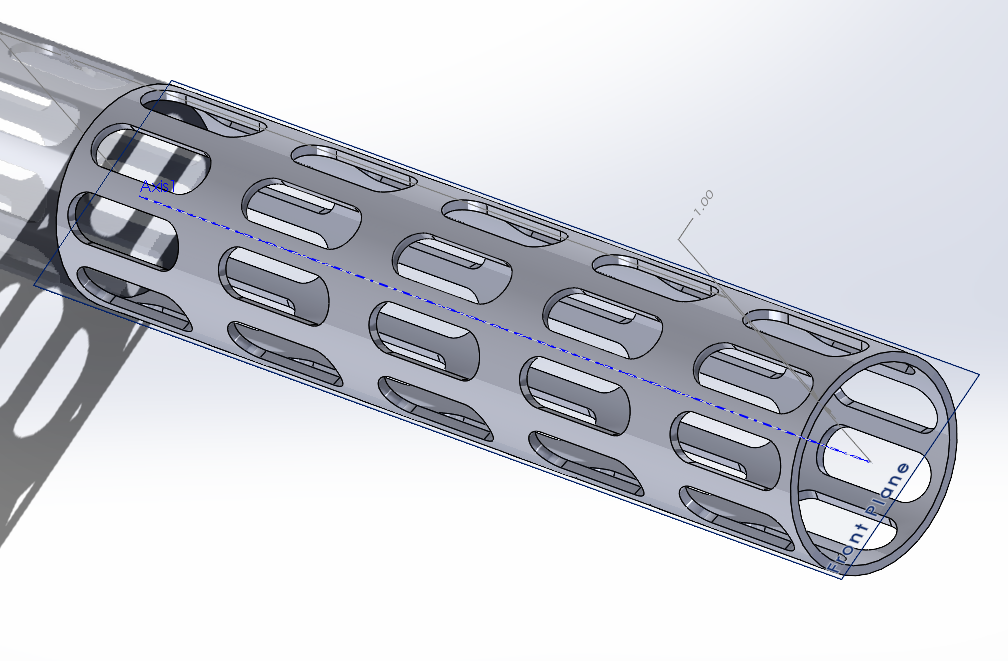

Once the cylinder was created, I created a centerline that measured 100 mm which went all the way through the front plane of the cylinder. In the “sketch” window using the “straight slot” button, I created a slot that was 10 mm in length, 5 width, 4 mm from the bottom portion of the cylinder, and 2.5 mm radius for the semi-circles at the top and bottom portions of the slot.

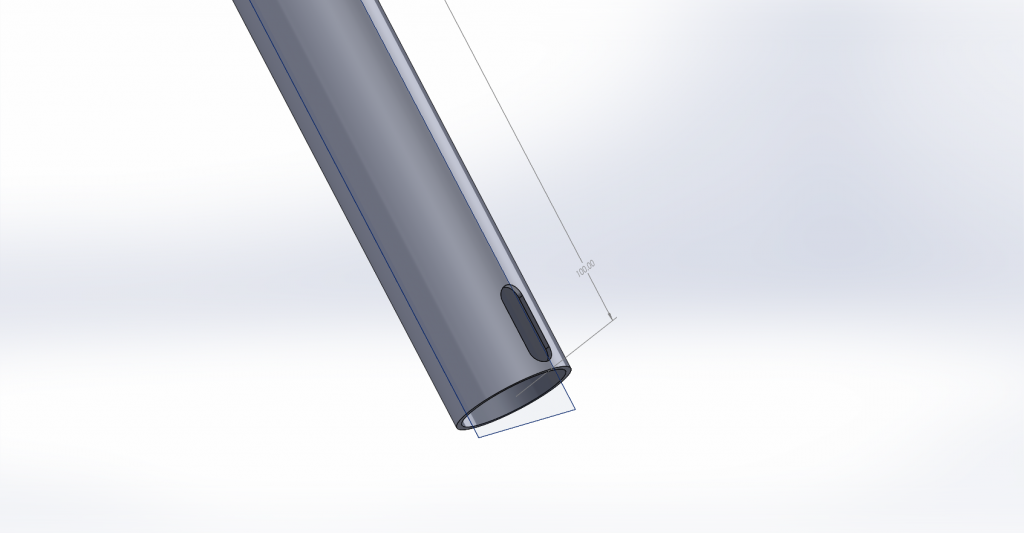

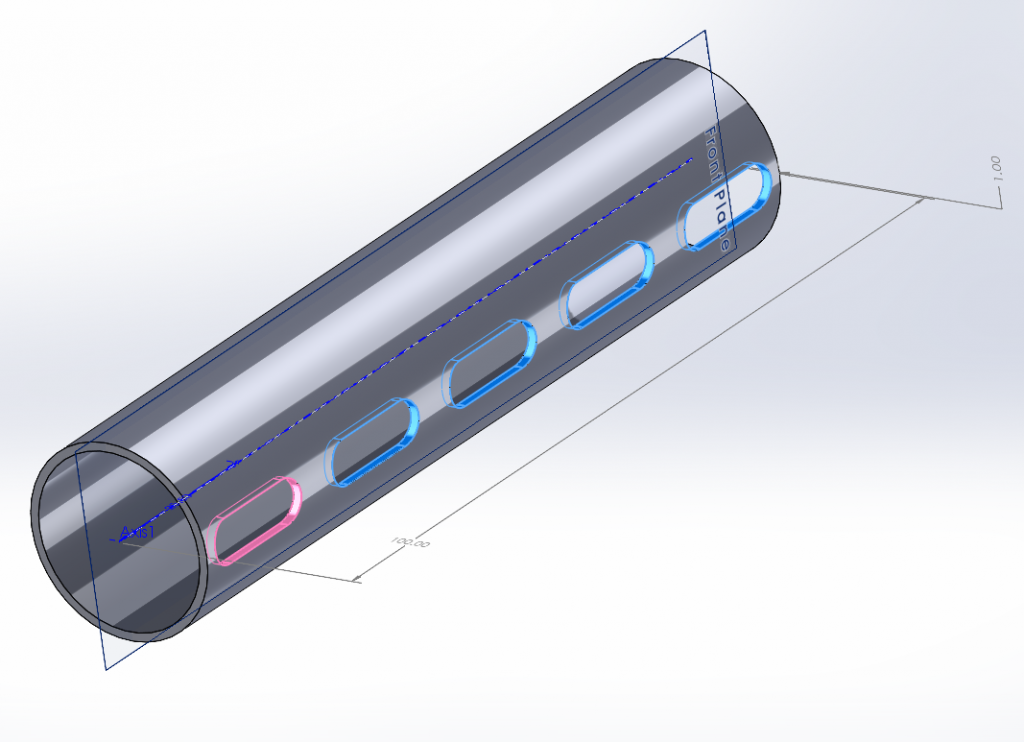

I then used the “extruded cut” and selected the “through all” button and cut out the slot into the cylinder, beginning the creation of the mesh-like pattern that is going to be copied all over the cylinder. In order to make the process of creating the pattern easier, I created a “geometry axis” in the cylinder in order to create an axis through the middle of the cylinder.

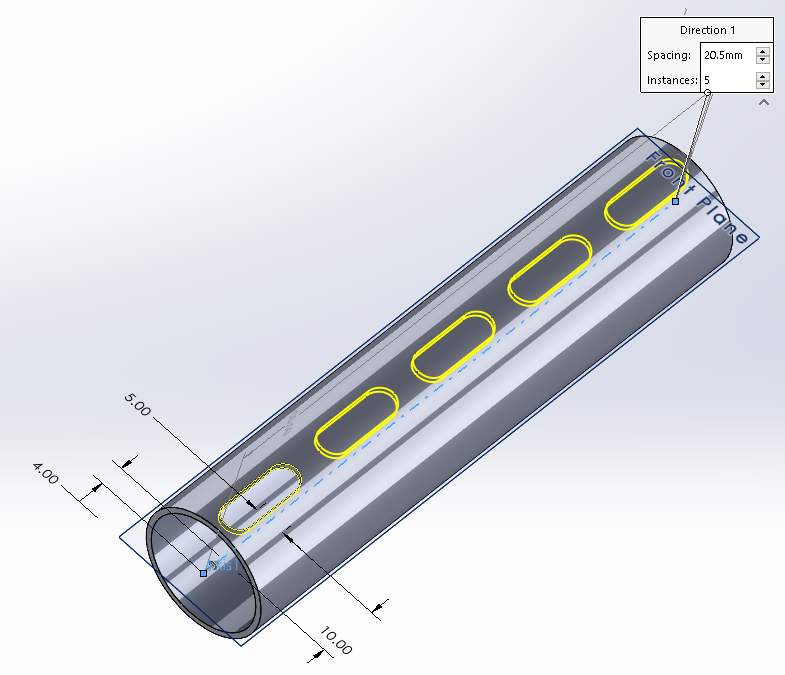

Once the axis was created, I was able to use the “linear pattern” tool while highlighting the extruded cut and the axis in order to create 5 slots that were each spaced out 20.5 mm.

For the final step, while highlighting the linear pattern, I used the “circular pattern” tool and created 9 patterns that were repeated all over the cylinder creating a mesh-like pattern.

Finally, I finished the product by downloading both the SolidWorks and STL files for the design and saved them into a ‘box’ file.

FINAL THOUGHTS

I AM SO HAPPY! I was so proud of myself for actually creating a SolidWorks design and was so accomplished after seeing the final product and “swinging it around” to see all of the dimensions and properties the design had. After looking up different stent designs I soon figured out how simple the design is, but that is okay since this is my first design and might lead me to create a more “intricate” and accurate design of a surgical stent. It was very hard at first since I was very unfamiliar with all of the functions and tools that were present in SolidWorks so I wasn’t sure how to approach things/design things at first glance because I was so overwhelmed with all of the functions the program had to offer. I was struggling to do basic functions and commands because of how unfamiliar I was with the whole thing especially since they really don’t show you how to use CAD and SolidWorks in BME. I really struggled with the part where I had to create the linear design because at first, I did not create the axis in order to give the program a reference line to create the pattern, but I once learned how to do it and was able to generate the design I wanted.

One thing that I feel I would like to improve on and learn more about it how to create designs on more than one plane. I would like to learn how to work in multiple planes at the same time in order to create things more efficiently and possibly create more intricate and better designs. I also really want to learn how to design a product around an image, or specifically use a reference image to create something in SolidWorks like a hearing aid or maybe even a skull segment using a CT scan/images.

I ACTUALLY 3D Printed my design so I could see beforehand how the stent would look and after feeling the material I realized that maybe for the next design, I would want to use a more flexible material (since it broke after playing with it a little) and with a better pattern which would allow for max support while also not taking up too much space where possible RBC (red blood cells) could get caught and cause another obstruction/coagulate and create more problems than it was supposed to fix.