For my 3D printing project, I decided I wanted to add some decor to my room and what better way to do that then print my favorite animal – a cat! Previously, I had zero experience with 3D printers, so this was a nerve wrecking task to walk into, however, I am happy to report that it ended up being less complicated (but still frustrating) then I anticipated.

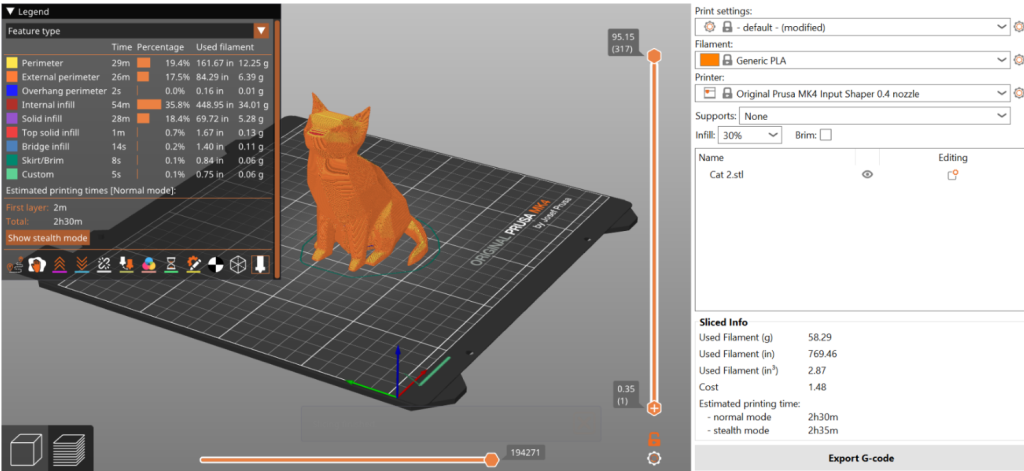

To go about my 3D print, I used the Original Prusa MK 4 printers in the Nolop Lab at Tufts with purple PLA filament as my material. I optimized the print time and material cost by scaling down my figure in size and choosing a lower infill level as shown below.

Now I was ready to print! Here is how my printing process went:

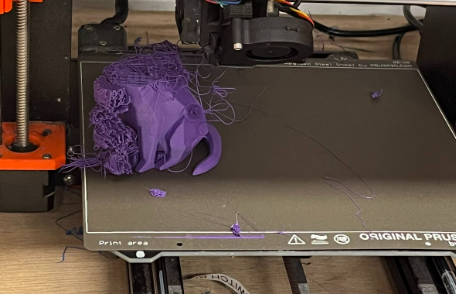

Trial 1 – As advised, I stuck around for the first 30 minutes of printing, as I was told that most prints that fail, fail within that time frame. Sadly, my print was part of that statistic. Around the 20-minute mark, the printer stopped working.

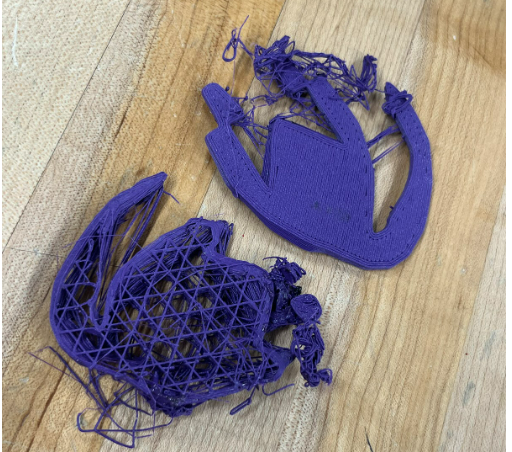

Trial 2 – I reached out to the student workers at Nolop. One advised me to try slicing on the website rather than PrusaSclicer, so that’s what I did. I also tried to resize my figure to 60%, as I had done in PrusaSclicer, but, for whatever reason, the website did not process this and started to print a larger size then I would have liked, resulting in 4.5 hours of print time. Given that I was already frustrated, I decided to let the print continue. Two hours in, and to my surprise, everything seemed to be moving smoothly. That is until I came back three hours later, expecting to find a beautiful figure, but instead finding my cat figurine decapitated. A few Mechanical Engineering students saw my misfortune and suggested I add supports to my figure.

Trial 3 (Third times a charm?!) – After a (much needed) week break from 3D printing, I decided to give it another shot. This time, I not only added supports, but decreased the size of the object to 50%. My rational was that a smaller figurine meant less printing time, and therefore, less time for things to go wrong. In this trial, I also learned how to change the filament myself! After 3 hours of print time, and lots of prayers, I came back to my cat figurine completed and intact!

I am honestly very happy with my finished cat figure. In addition to coming out sturdy, it was a very cute addition to my room decor. Although frustrating, I loved watching something created digitally take form in real life. This experience made me realize the versatility of 3D printing as its applications can be endless and allows us to fabricate objects that would be difficult with traditional technologies. For example, 3D printing opens the door for patient tailored implants as traditional methods often require standardized sizes and shapes which may not fit the patient as well. Moreover, 3D printing allows for more intricate jewelry designs which may not be captured as well in traditional methods like casting without considerable labor. Overall, given how useful 3D printing is, I am happy to have had this experience and hope to hone my skills further!