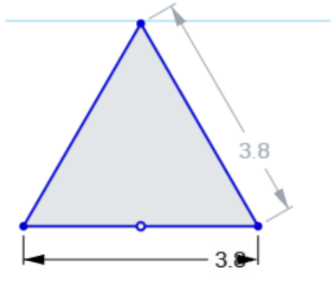

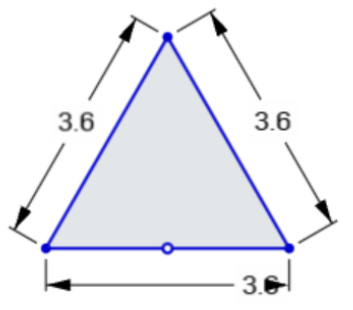

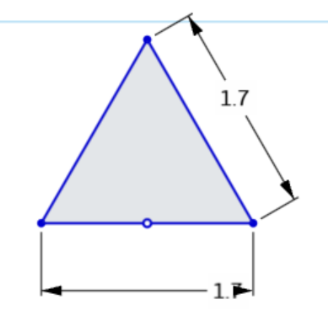

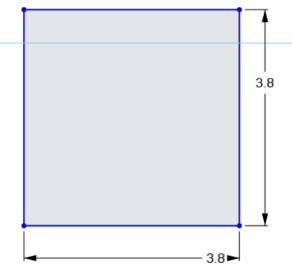

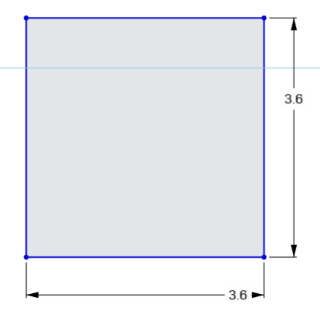

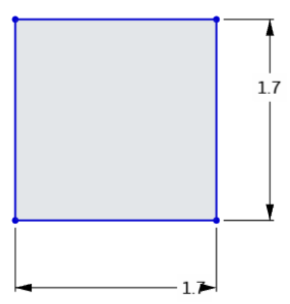

Just as with the previous assignments, I had no previous experience with laser cutting. As someone of Egyptian heritage, I thought it would be pretty neat to recreate the Pyramids of Giza. For the dimensions, I used the help of AI to scale down the life size of the pyramids into something I can reasonably laser cut. With a scale of 1:200, I created three differently sized equilateral triangles for the sides of the pyramids and squares that were appropriately sized for the base.

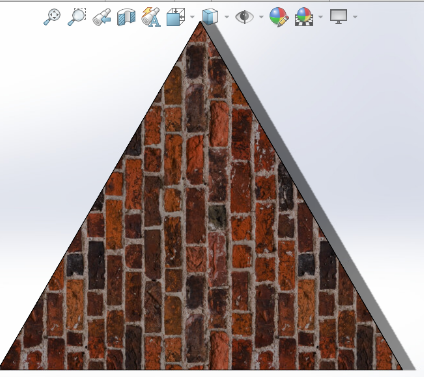

These polygons were made through a CAD software known as OnShape. This software was recommended to me by one of my Mechanical Engineering friends to avoid the slowness and glitching that often comes with using Solidworks through a PC. However, Onshape did not offer the texture feature and so I had to resort back to Solidworks to add a brick texture to my pyramid sides to better replicate a realistic Egyptian pyramid.

To laser cut, I went to Nolop at Tufts and used their Universal Laser Systems laser cutter. The aim was to engrave the brick texture within the pyramid sides. However, when I went to laser cut, the brick texture did not show up on Adobe Illustrator. Given how long it took me to navigate Solidworks the first time, I accepted defeat and decided to proceed without the engraving.

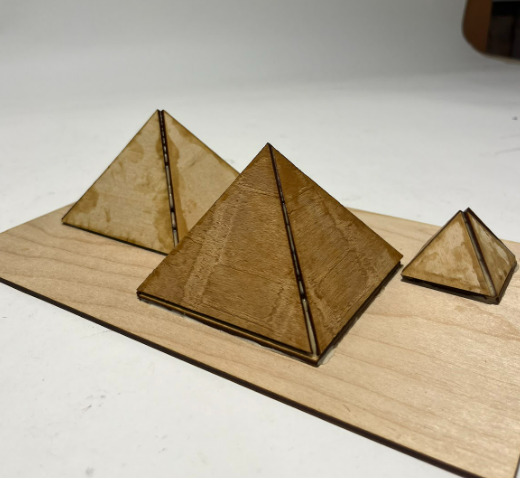

As shown above, I made and cut four duplicates of each sized triangle as well as the corresponding square base. Afterwards, I used the cut parts to assemble the pyramids using wood glue. Honestly, this was the most frustrating part of the project as the pyramid sides kept falling apart during assembly. Assembly of the smallest pyramid was especially difficult, and it would’ve definitely been nice to have an extra pair of hands.

After assembling the pyramids, I thought it would be nice to give them all one base on which they can stand on cohesively. To do so, I measured out an appropriately sized rectangle and laser cut it.

Afterwards, I organized the pyramids on the base in way I found to be most aesthetically pleasing (and accurate to the real model) and glued the parts on accordingly. And voilà, I had my completed model of the Pyramids of Giza!

In this project, many things, such as the engraving of brick texture, did not go as planned. Moreover, gluing the parts and assembly I found difficult and frustrating. That said, overall, this project was fun and informative. I learned just how easy laser cutting can be once you get the hang of it. Laser cutting is also incredibly precise, quick, and versatile. This makes it an ideal tool to use when fabricating objects that would be more difficult to do so with more traditional technologies. Intricate metal jewelry, for example, may require designs with fine, complex cuts that would be difficult to achieve with traditional techniques, but can be precisely followed with a laser cutter. Laser cutting can also handle very thin or fragile material such as fine fabric or thin plastics that would tear or deform under traditional machining processes. Thus, laser cutting technology may be an ideal choice if your design involves intricate details, sensitive material, or requires quick design changes (ideal for rapid prototyping).