For this assignment, I wanted to design something that fits the requirements of the assignment and also useful to me. Struggling to find storage space in my room, I decided to design and build a shelf. After exploring various designs online, I came across a three-shelf structure that suited my needs. To fabricate it, I used the Universal VLS 3.60 laser cutter in Nolop.

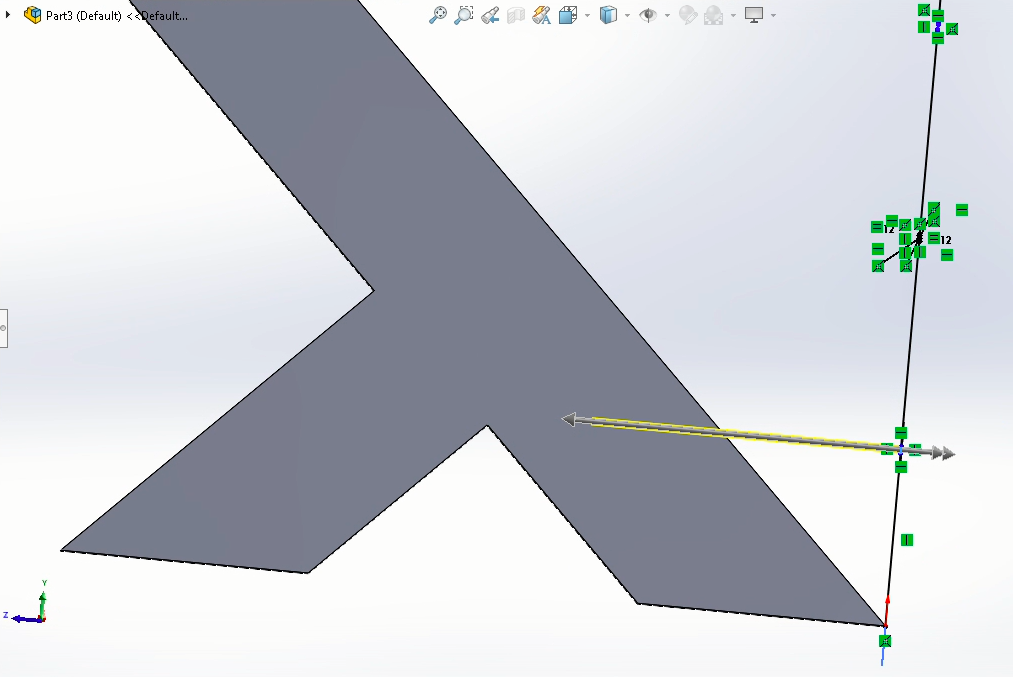

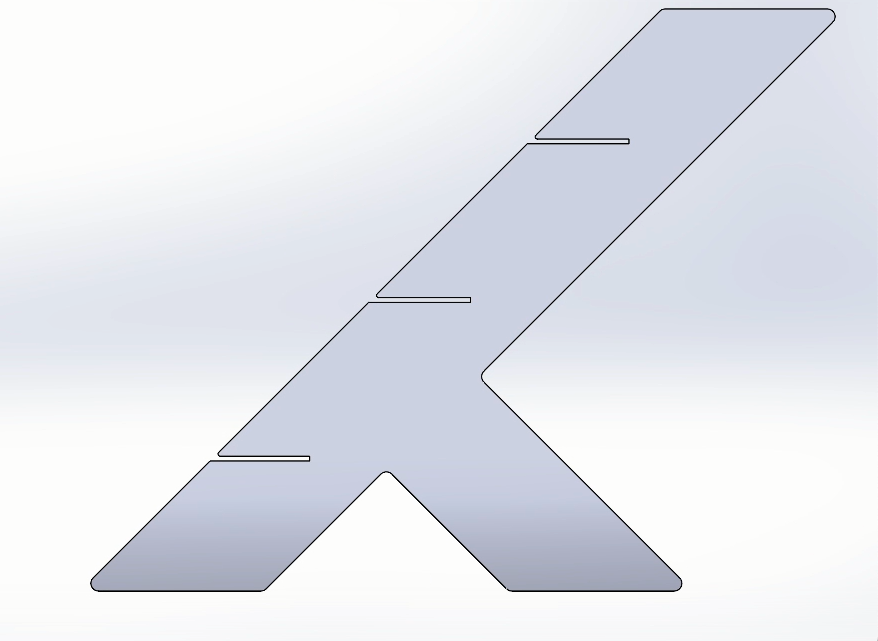

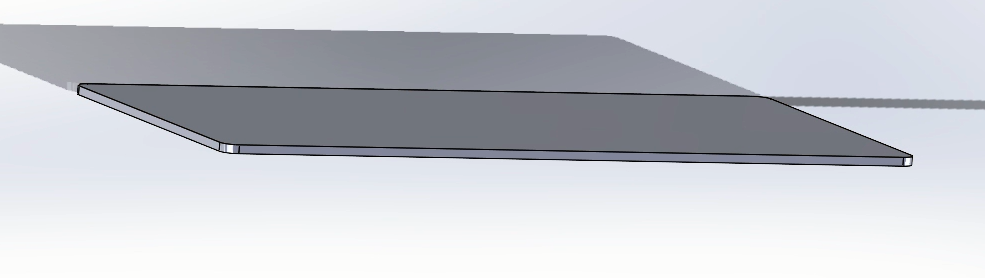

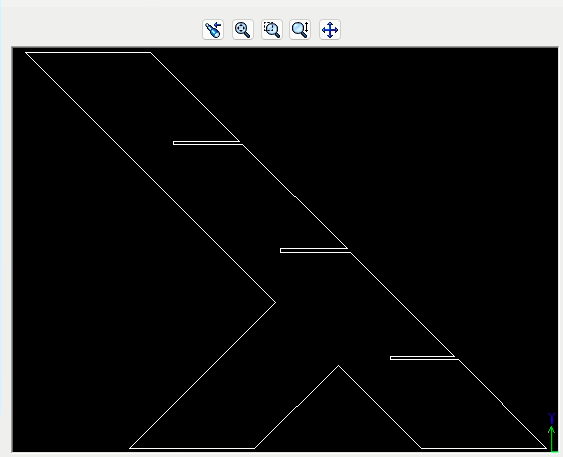

The most time-consuming part of the process was creating the CAD model in SolidWorks. The design consisted of two standing legs and three shelves. While the shelves were relatively straightforward to model, the legs required precise slits and 45-degree angled sides to ensure a proper fit and standing. The corners of the shelves and the legs were round up using the fillet option in SolidWorks with a small radius to avoid sharp edges. Once the modeling was complete, I exported the files as .dxf and opened them in Adobe Illustrator for laser cutting preparation.

Transitioning to the laser cutter was a challenge. I was more familiar with the Bray Laser Cutter, which operates differently. However, the Nolop tutorial guide provided clear, step-by-step instructions, making it easier to navigate the machine. I used 3mm Birch wood for both the shelf and the legs. Cutting the parts was quick—I repeated the laser cutting process for both legs and all three shelves. Without accounting for setup and adjustments, the actual cutting time took less than five minutes.

Once all the pieces were cut, I assembled the shelf by gluing the shelves into the legs using wood glue. Initially, I encountered an issue with the shelf dimensions. The shelves were too small, and after scaling them up uniformly, they became too large. I had to unlock proportional scaling in Adobe Illustrator and adjust the width separately to achieve the correct fit.

This 3D object seems like a good example of when traditional methods would be more difficult to use. The precision required for the slits shows the advantages of laser cutting. Traditional fabrication methods would have made it difficult to achieve the exact slot dimensions needed for a snug fit. Additionally, the 45-degree angles would have been more challenging to execute with conventional tools. Other examples where laser cutting is particularly beneficial include creating objects with thin profiles and intricate geometries, such as gaskets, puzzle pieces, snap-fit components, and parts requiring precise tolerances.

I would say a limitation of laser cutting is that it can’t cut more than 3mm for birch wood which limited the thickness of the wood I can use for this shelf, making it less sturdy.

I would use a laser cutter for objects with complex geometries and when I need precise measurements, fast fabrications, and for thin models.

This project showed how laser cutting allows rapid and precise fabrication of complex designs that would otherwise be difficult to achieve with traditional methods.