Kirby!

To demonstrate our molding and casting skills, we decided to creat Kirby display! We initially wanted to make a candle and candle holder, but we unfortunately lacked the necessary materials. As such, we pivoted and began exploring new ideas. We ended up deciding on a Kirby display, as we enjoy him and though he would not be too difficult to mold and cast. I created the necessary molds using Autodesk Fusion, which were 3D printed by Vio Ta and Maya DeBolle. Molding and casting was then performed by Amanda Lee, Vio Ta, Maya DeBolle, and Omar Da’darah.

Sketches

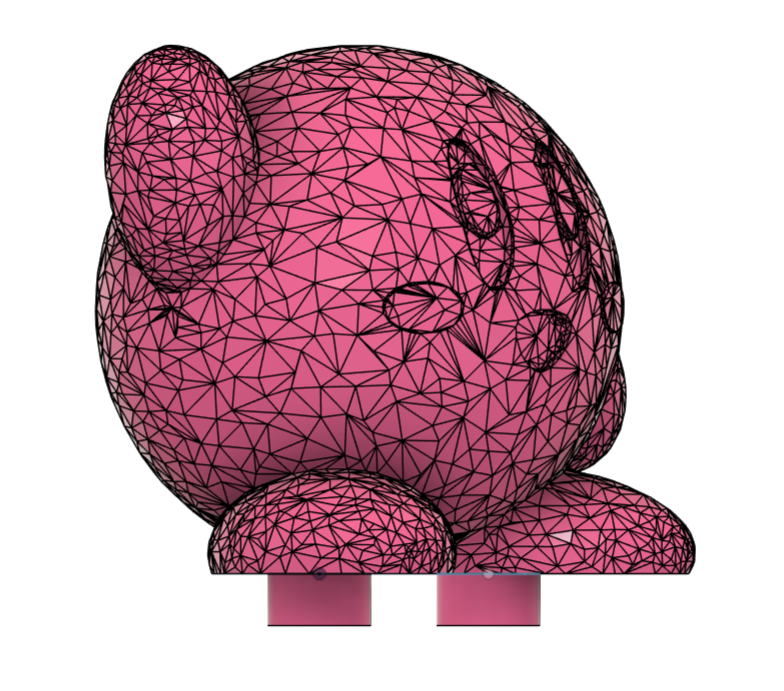

CAD Models

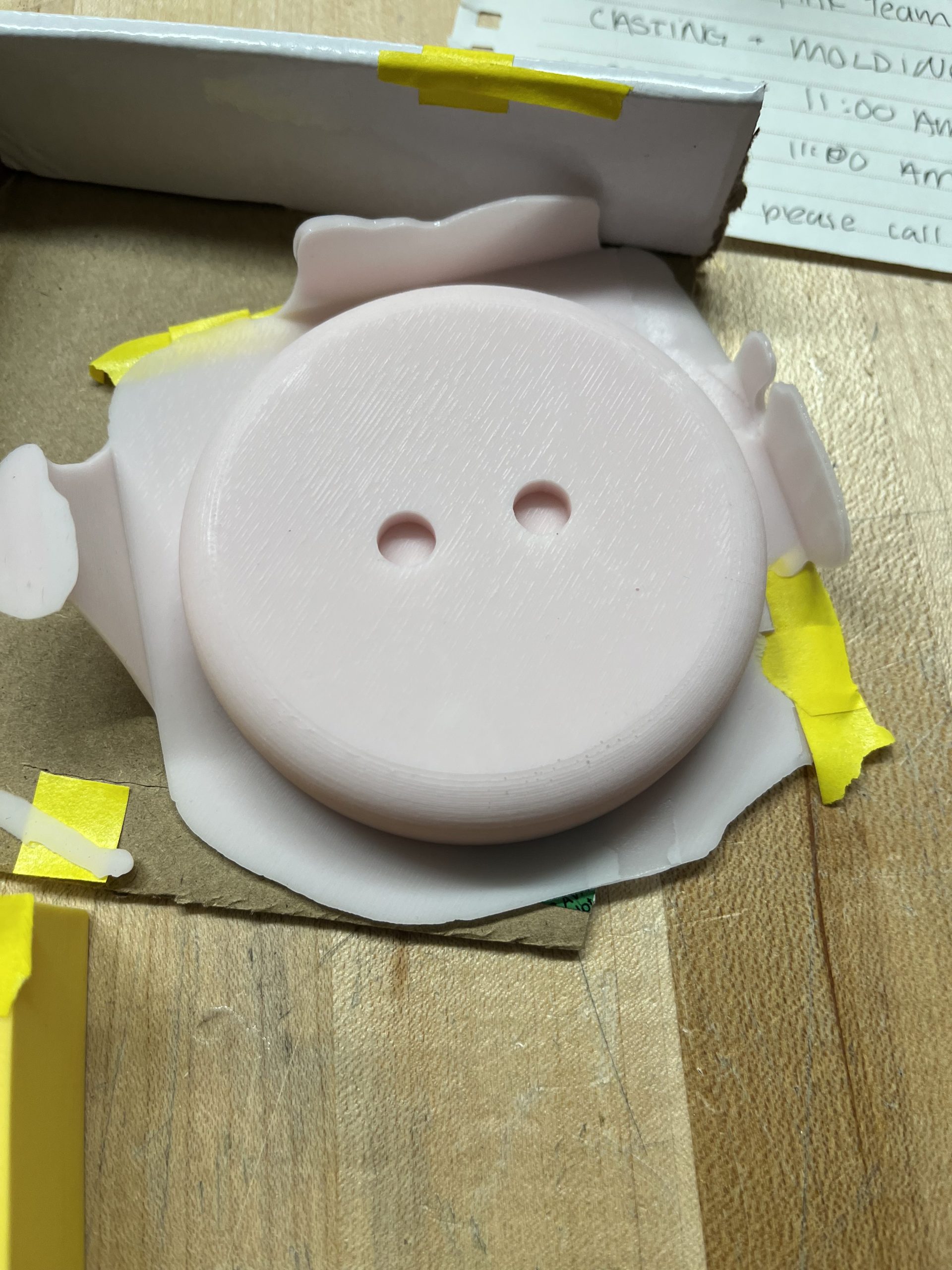

One-Part Mold for Base

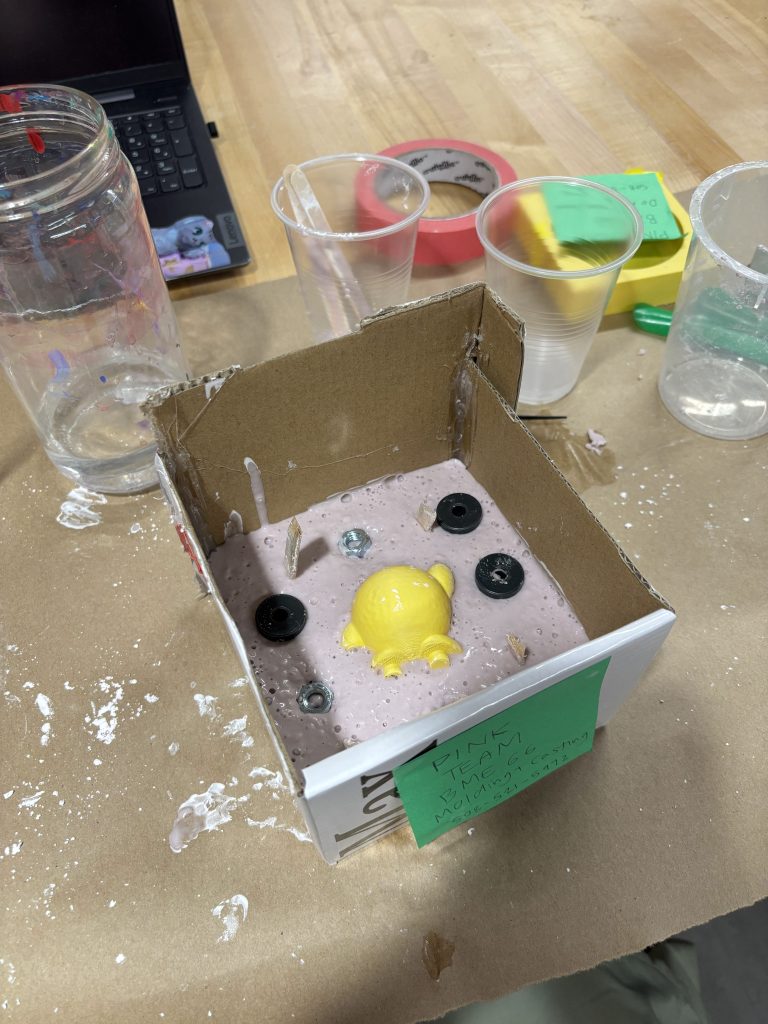

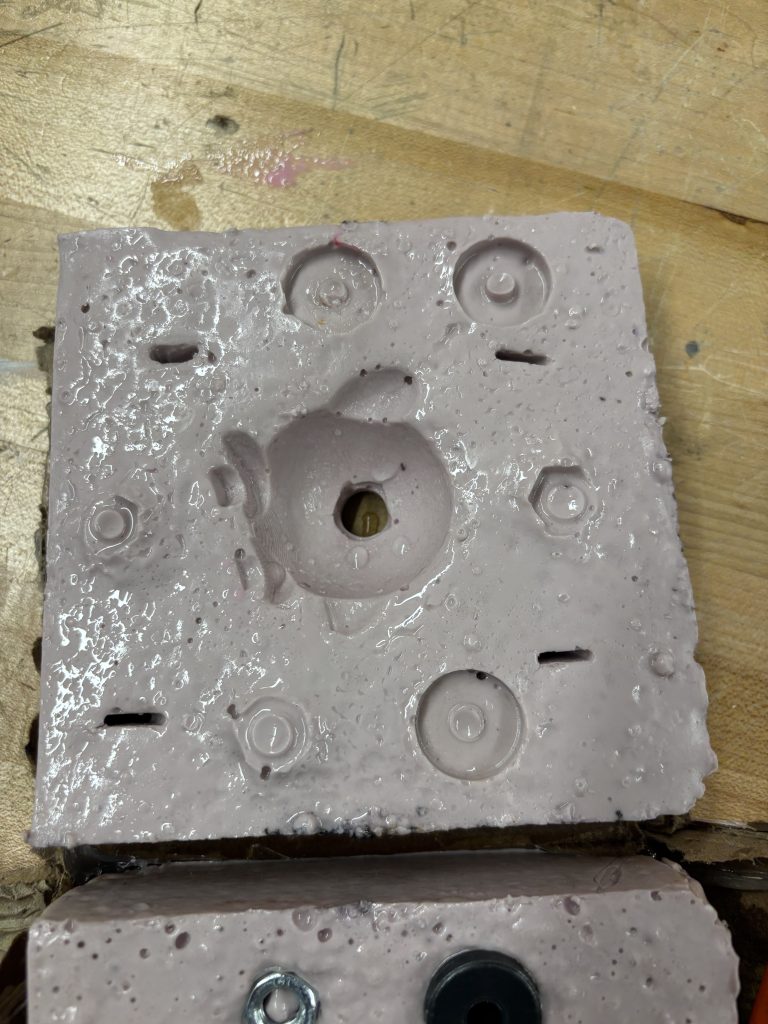

Two-Part Mold for Kirby

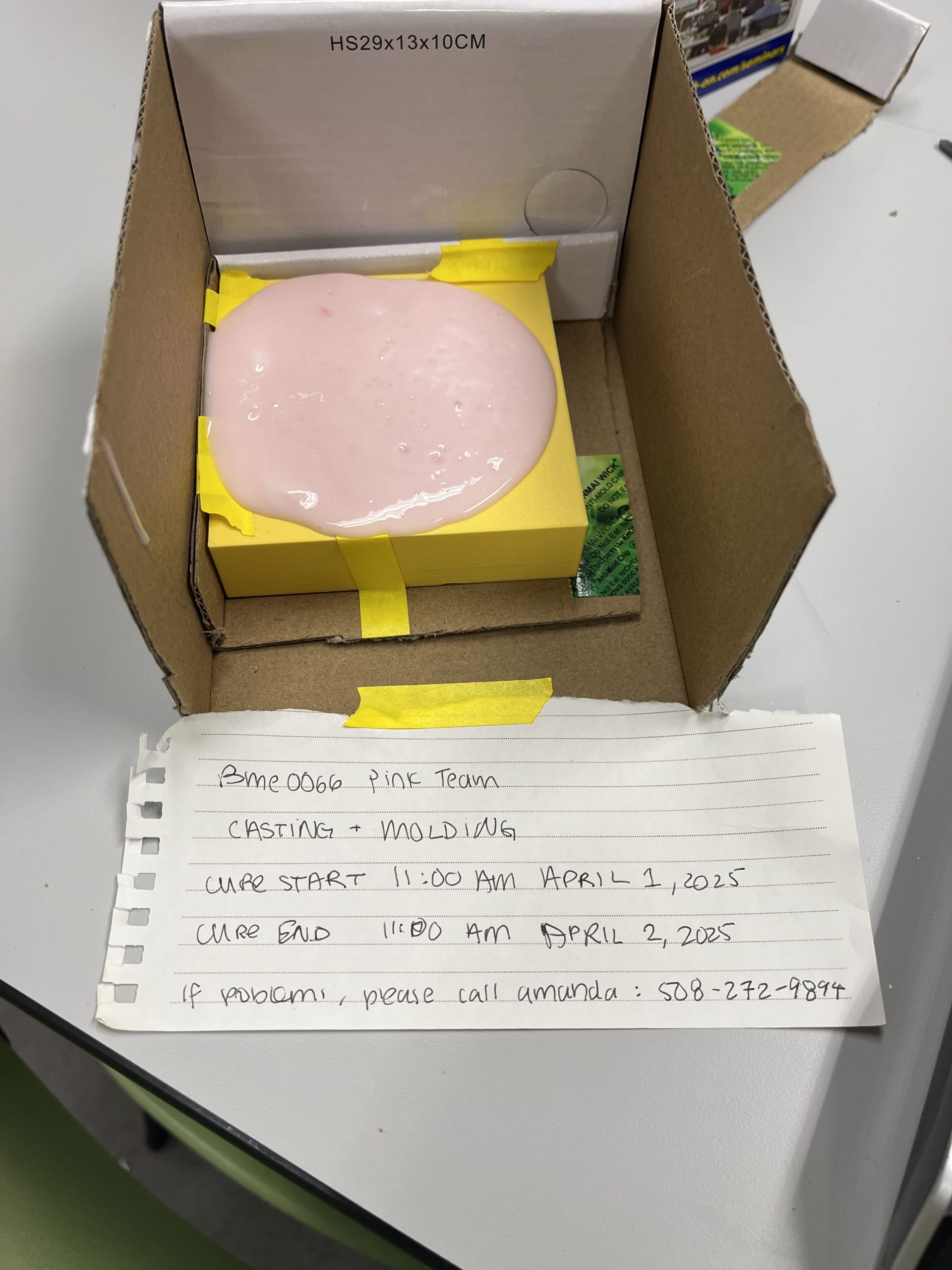

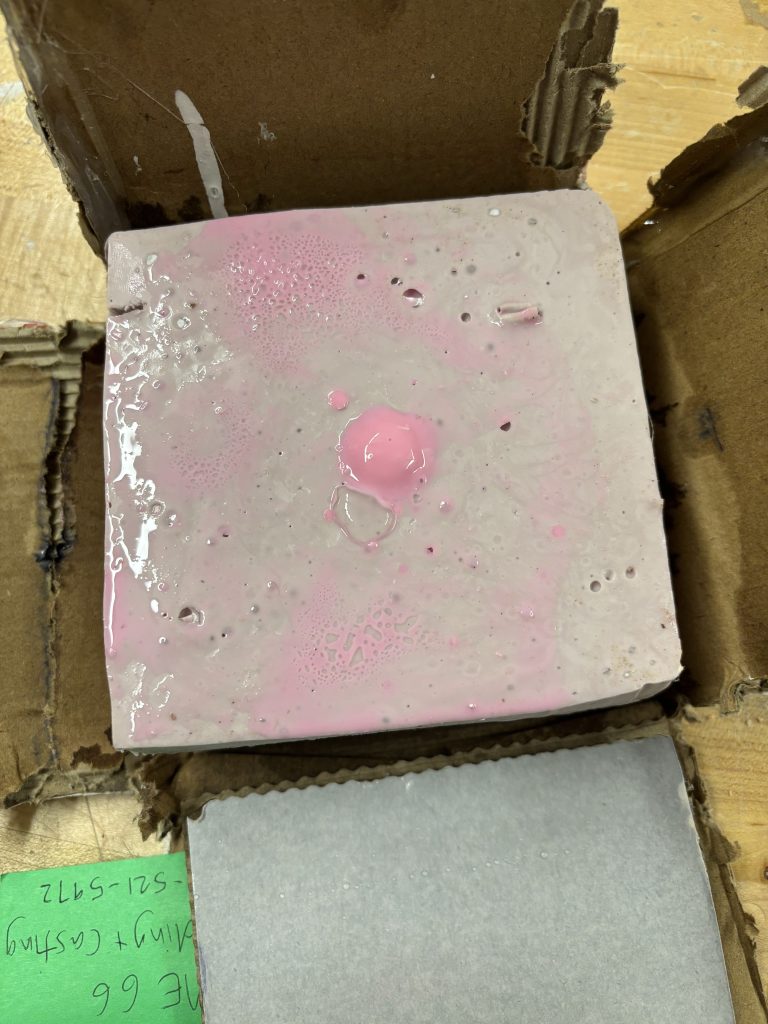

We split the display into two parts. The base of the display was casted with Smooth-Sil 940 using a one-part 3D printed PLA mold. Kirby was casted with Mold Max 30 using a two-part Alja-Safe. The mold was created by using a 3D printed PLA Kirby to imprint the desired features on the Alja-Safe. The main reason we chose to use Smooth-Sil 940 and Mold Max 30 was because they were both pink and we wanted Kirby to be the correct color without having to paint over him.

Pouring the Mold Max 30 to cast kirby ended up being more dfifficult than we anticipated, especially when compared to the Smooth-Sil 940. The mixture was fairly viscous and difficult ot pour at a constant rate. As such, air bubbles became trapped during casting and were present in the final product. We ultimately learned that a larger pour hole and vents to allow air to escape is necessary to prevent air bubbles from forming and getting trapped in the cast.