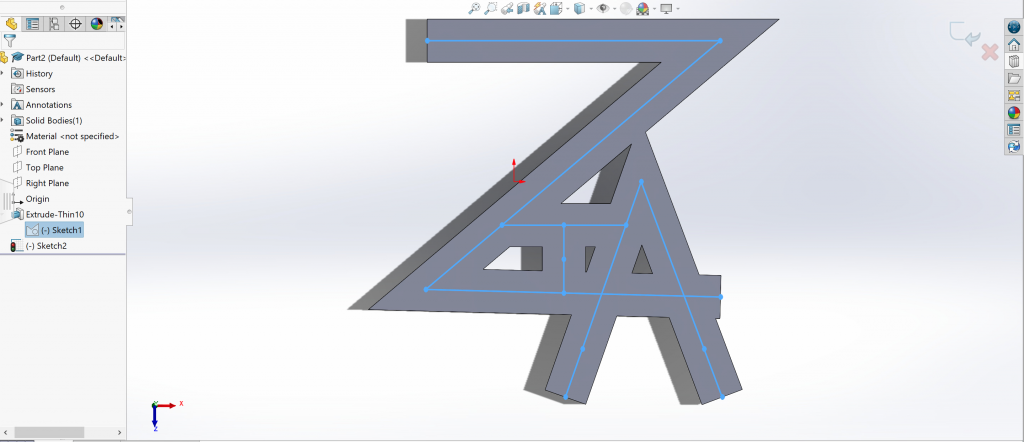

Zari’s First 3D Print!

For my 3D Printing Assignment, I decided to print part of my the main part of my CAD assignment, my initials. I was a little hesitant to print the entire assembly because I wasn’t sure if all of the pieces were correctly adhered together.

I started by finding one of the available Original Prusa i3 MK3S+ 3D printers in NOLOP. Although we had taken a tour and had introductions to using the 3D printers in both NOLOP and SciTech, the most difficult part of printing my CAD design was actually getting hooked up to the printer. The first mistake that I made was saving my file incorrectly. The file was originally saved as a SLDPRT file instead of an STL file but it was corrected easily by just opening SolidWorks and re-saving the file under the correct file type. Secondly, my design was standing up vertically on the bed so I had to orient it at -90 degrees OctoPrint. My design was also too big for the printer bed, but I was able to size it down on OctoPrint without having to go back on Solidworks.

Once these mistakes were corrected, I was able to start the printing process. Although the OctoPrint estimated the print to take around 2 hours, it was finished after around 45 minutes.

The final print showed me the some of the small design errors to keep in mind in the future. The first thing would be to print all letters and logos backwards if it was required that the top be smooth. As you can see in the picture below, there are ridges in the print which is caused from each layer being filled in. In the future, I will also be cognizant of how thick the extrusion is horizontally because in my final print it is hard to differentiate between the I and the A.

At the end of the process, I was able to fully understand the various benefits and differences of using a 3D printer versus a Laser Cutter. I could have technically gotten similar results with this design using a Laser Cutter, but I would have had to used a material with a similar thickness. Therefore, anything with a height above the thickness of an acrylic/wood sheet couldn’t be created using traditional methods like Laser Cutting. For instance if I wanted to print a 3D, anatomically-correct model of the heart, I would have to use a 3D printer because a laser wouldn’t be able to create a solid model with the complex and non-geometrical edges that a heart has.