by Aaron Johnson, Post Doctoral Research Associate

In addition to my work on international difference in engineering education, I am leading a second research project supported by the CEEO Innovation Fund. I have been working with Paul Grogan, an Assistant Professor in the School of Systems and Enterprises at Stevens Institute of Technology, and Sara Willner-Giwerc, an undergraduate student in Mechanical Engineering, to develop a LEGO EV3 workshop around concepts of systems engineering. If you’re not familiar with this discipline, systems engineering coordinates efforts across multiple disciplines to realize complex products. Systems engineering isn’t typically taught until graduate school, but my collaborators and I believe that it’s important for pre-college students to have an understanding of this field. Thinking about an engineering problem in terms of systems engineering concepts, such as specifying requirements for each subsystem, is a more sophisticated approach to engineering design. An understanding of systems engineering also promotes technological literacy and enables all students to understand how the technological, human, and natural components of a system affect the others in both positive and negative ways.

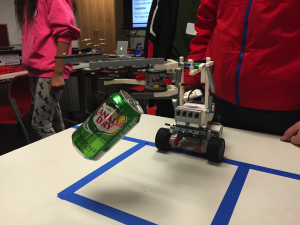

We developed our systems engineering workshop through multiple iterations and pilot studies over the past year. Our original idea for the workshop was to have teams of six students collaboratively build one “toxic waste disposal” robot. This robot’s task was to drive forward from a starting line, pick up an empty soda can representing “toxic waste,” and continue forward to deposit it in a safe disposal container. Two students worked together on each of the subsystems: the chassis, the manipulator arm, and the programming. The students could communicate their designs with the other subsystem teams through words and drawings, but they could not show the other teams their LEGO bricks. This constraint was designed to force communication between the groups.

We tested this activity with two different groups and were encouraged by the students’ ability to work together, despite not knowing each other before the workshop. The students also discovered a number of requirements that they needed to discuss; for example, the programming team needed to know how long the arm was going to be in order to program the robot to stop at a particular distance from the can. Despite these encouraging behaviors, we found the overall challenge to be too difficult. Students did not have enough time to make it to the testing stage, even when given three hours. And, when students tried to integrate their subsystems, they were unable to do so because there were still a number of important requirements that they had not discussed.

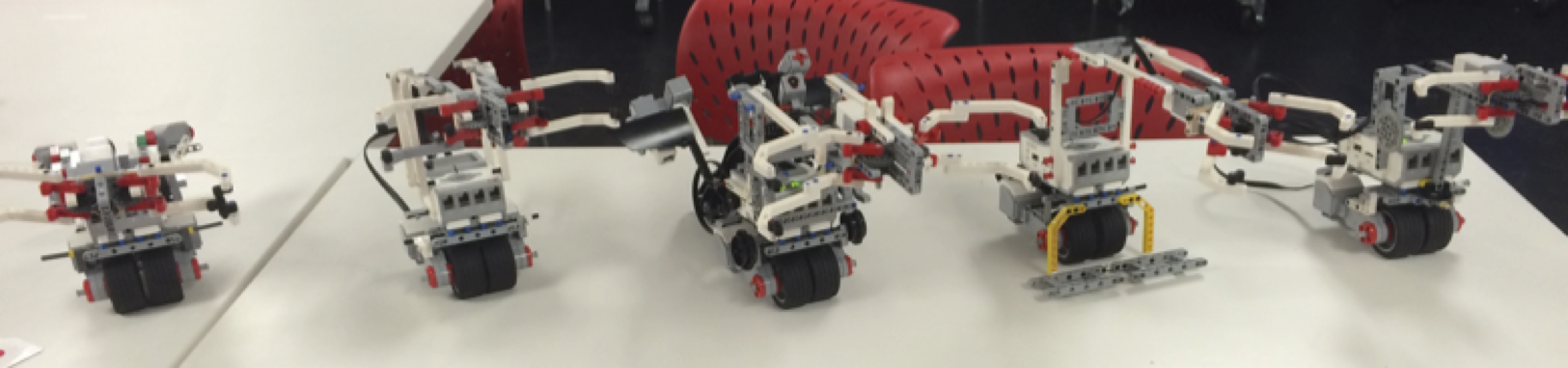

After these unsuccessful workshops, we redesigned the activity to be simpler and better focused on our systems engineering learning objectives. We kept the toxic waste disposal theme, but had students work in pairs to integrate a pre-built EV3 arm with a pre-built chassis. There were two phases to this activity: first, students had to retrieve a can on the front of a 3-inch platform. Once they successfully accomplished this, we put the can on the back of a taller platform (6.5 inches) and filled it with pennies. This required students to redesign their robot in the middle of the challenge, showing them how changes to one subsystem can propagate through the entire system. Students were able to accomplish these redesigned challenges, and were engaged and involved, even when their robot failed a test. They were so excited to keep iterating that we kept reducing our end-of-workshop clean-up time to allow for more tests. We were also encouraged by the diversity of solutions that students demonstrated, even when starting with the same two pre-built components.

We collected video data of students describing their robots and design decisions during three workshops, and analyzed this video to see how they engaged in systems engineering methods. This is the basis for a paper we will be presenting at the IEEE Frontiers in Education Conference in October. While students rarely used the language of systems engineering, such as “requirements” or “interface,” the videos do show students discussing systems engineering methods in a more familiar language. Students considered a number of requirements, like the height that their arm had to be above the table in order to clear the platform. They also tested their robots to find requirements that were not being satisfied, and then modified their design to satisfy these. These results are encouraging, as they suggest that students can understand and apply certain systems engineering methods when working with LEGO robotics.