What is Prusa Slicer or Slicers in general?

A slicer is a tool that helps convert the objects you have created in software like ShapesXR, TinkerCAD and BlocksCAD into instructions that a 3D Printer can use to actually create your object. Most Slicers can take a variety of files but often export into a file type named gcode.

What does gcode have that I don’t?

While stl, and obj files are great, they don’t include specific instructions that 3d printers need! Things like infill, printing temperature, speed, and filament are things that the gcode file will know that the other kinds of files don’t.

The Infill

The infill is the supports and filling that the machine will put inside of your print. The infill determines the sturdiness of the object and is often quantified as a percentage. This percentage refers to how much of the inside of your print is filled in, with 0% being the lowest and completely empty, and 100% being the highest and completely solid. The higher the percentage the more solid your object will be, but it will be heavier and take longer to print. Lower infill percentage will make your project weak, but it will be lighter and take a lot less time to print.

3D Printing is complicated, how do I make my project succeed?

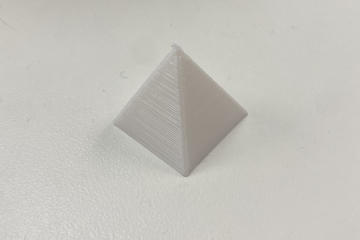

If not prepared properly, a print job can easily fail. However the Prusa Slicer application gives you many tools to help increase the odds of success for your print. The biggest help can be making sure your piece lays as flat as possible on the base of the printer. This will ensure that most of the piece will be naturally supported by the print itself and will not collapse due to difficult or precarious overhangs. You can also increase the success of your build by including support. Supports are small weaker pieces of the filament that are meant to support your build while it is printing and then can easily break off and be discarded. Supports can be helpful when you cannot get your build to lay completely flat, or have overhangs or areas that may seem like they will fail. While they can increase build time, the increased success more than makes up for it.

Making your print succeed can also start during the design process. Try your best to avoid making extremely complex shapes or thin lines. Some things may work in the CAD world, but do not translate to our world with real physics! Large and heavy overhangs or objects hanging from thin lines will almost certainly fail if not properly supported.

Can it slice fruit?

Since

it is a computer software, it cannot slice real fruit. However, if you were to

make a 3D Model of a piece of fruit it can most definitely slice and prepare

that model for print!

0 Comments