Maglev: Magnetic Levitating Trains

Abstract

Maglev trains use magnetism to levitate above the tracks on which they travel. They are faster, more efficient, and more environmentally friendly than modern wheeled trains. It may be that one day soon, maglev technology will be commonplace throughout the world. This article reviews the history of these trains, how they work, as well as their benefits and drawbacks. It also discusses the importance of electrical engineering in developing maglev, and how electrical engineers can make this technology the next transportation revolution.

Introduction

Imagine a train without wheels. Instead of rolling along the track, it quietly floats above and glides smoothly from origin to destination without ever touching a rail. This may sound like science fiction, but instances of this technology already exist in a number of places in the world. They are known as maglev trains (derived from the term magnetic levitation). These futuristic locomotives offer many new and exciting possibilities for travel. They have the potential for being faster, safer, and more energy efficient than conventional transportation systems. Although such trains are few and far between as of now, they are a hotbed of research in the electrical engineering community. As a result, maglev may be commonplace sooner than you’d think.

History of Maglev

The fundamental ideas behind maglev technology can be traced back to the early 20th century. Much work went into laying the groundwork for these trains, including the development of electric motors and research in magnetism. A few scientists, namely Robert Goddard and Emile Bachelet, even dared to propose a vehicle that would float using magnets (Yadav, 2013). In 1934, a German man by the name of Hermann Kemper was given a patent for the first concept of a magnetic, levitating train (Yadav, 2013). It wasn’t until the 1960s that the idea really began to manifest. At this time, Germany and Japan began researching the potential of maglev. During the 70s and 80s, both countries made great progress in developing these trains. Germany built and tested a string of prototype maglev systems and called their design the TransRapid (Figure 1). The trains achieved speeds of over 250 mph (402 kph) on the test track (Luu, 2005). Japan also tested two series of their own designs, called the ML-500 and later the MLU. Their trains were able to exceed 300 mph (483 kph) (Luu, 2005).

Figure 1

Transrapid on testing center in Germany near Bremen. Source: © Stahlkocher / CC BY-SA 3.0

Japan continued development of its maglev technology into the 90s and beyond. They tested a new series, called the MLX, which broke 350 mph (563 kph) in 2003 (Yadav, 2013). No commercial lines have been established in the country, but they are still carrying out research. In Germany, a commercial TransRapid line connecting Berlin and Hamburg was proposed in 1992. However, in 2000, the government shut down the project (Luu, 2005). Not all was lost, though, as the Chinese took notice and commissioned the Germans to build a TransRapid train in Shanghai. The Shanghai Maglev (Figure 2), which resulted from this venture, is now the only high-speed maglev train in commercial use. It carries passengers a distance of 19 miles (30km) in 8 minutes, reaching a top speed of over 250 mph (431 kph) (Coates, 2004). Thus China has quickly become a large player in the worldwide maglev market. The country plans to continue development of its maglev infrastructure.

Figure 2

Shanghai Maglev leaving the Pudong International Airport, with the Shanghai Transit Map rail map showing the route to Longyang Road. Collage sources: © Alex Needham / Public Domain and Metropedia

How Does it Work?

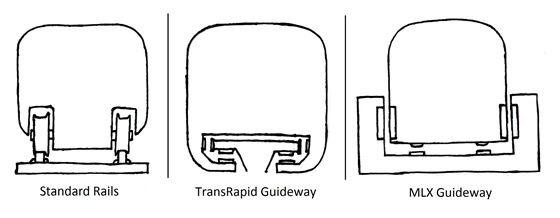

Maglev trains do not have wheels or rails. As shown in Figure 3, they have guideways, and they float down these guideways without ever touching them.

Figure 3

Comparison of Wheel-Rail versus Guideways. Source: Author, derived from Lee (2006).

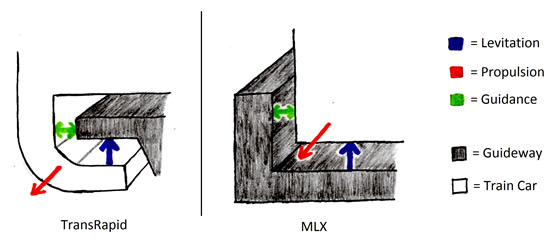

There are three essential parts to achieving maglev functionality: levitation, propulsion and guidance (as seen below).

Figure 4

Levitation, propulsion, and guidance in maglev. Source: Author, derived from Lee (2006).

Levitation

Levitation is the ability for the train to stay suspended above the track. There are two important types of levitation technology:

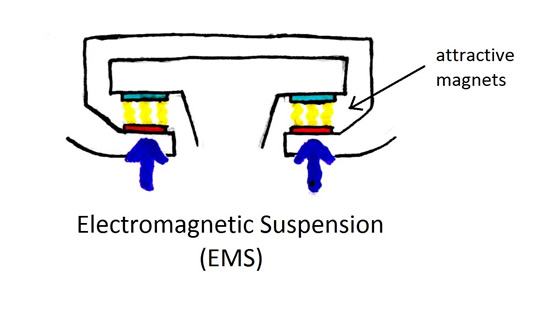

- Electromagnetic Suspension (EMS): EMS (Figure 5) uses the attractive force of electromagnets placed on the guideway and on the train to achieve levitation. The benefits of this method are that it is simpler to implement than Electrodynamic Suspension (discussed below), and that it maintains levitation at zero speed. The drawbacks are that the system is inherently unstable. At high speeds, it becomes difficult to maintain the correct distance between train and guideway. If this distance cannot be kept, the train will fail to levitate and come grinding to a halt. To account for this, EMS requires complex feedback-control systems to ensure the train is always stable (Lee, 2006).

Figure 5

Electromagnetic Suspension (EMS). Uses attractive magnetic forces. Source: Author, derived from Lee (2006).

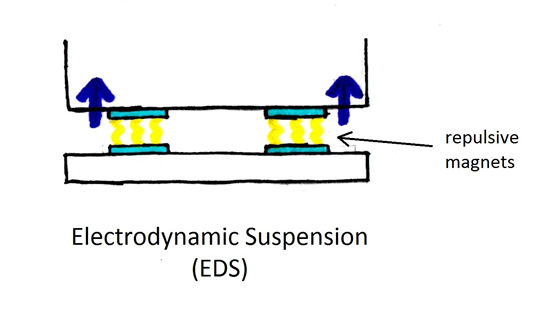

- Electrodynamic Suspension (EDS): EDS (Figure 6) uses the repulsive force of (superconducting) magnets placed on the guideway and on the train to achieve levitation. The magnets move past each other while the train is running and generate the repulsive force. The benefits of this method are that it is incredibly stable at high speeds. Maintaining correct distance between train and guideway is not a concern (Lee, 2006). The drawbacks are that sufficient speed needs to be built up in order for the train to levitate at all. Additionally, this system is much more complex and costly to implement.

Figure 6

Electrodynamic Suspension (EDS). Uses repulsive magnetic forces. Source: Author, derived from Lee (2006).

Propulsion

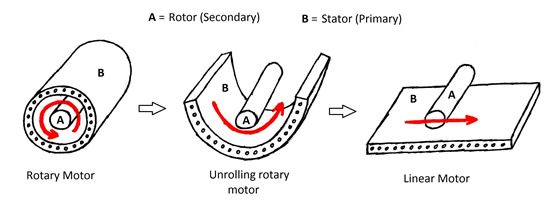

Propulsion is the force that drives the train forward. Maglev uses an electric linear motor to achieve propulsion. A normal electric rotary motor uses magnetism to create torque and spin an axle. It has a stationary piece, the stator, which surrounds a rotating piece, the rotor. The stator is used to generate a rotating magnetic field. This field induces a rotational force on the rotor, which causes it to spin. A linear motor is simply an unrolled version of this (see Figure 7). The stator is laid flat and the rotor rests above it. Instead of a rotating magnetic field, the stator generates a field that travels down its length. Similarly, instead of a rotating force, the rotor experiences a linear force that pulls it down the stator. Thus, an electric linear motor directly produces motion in a straight line. However, this motor can only produce a force while the rotor is above the stator. Once the rotor has reached the end, it stops moving.

Figure 7

Rotary motor versus linear motor. Source: Author, derived from Lee (2006).

When describing a linear motor, the standard is to use the term “primary” instead of “stator,” and “secondary” instead of “rotor.” In maglev trains, the secondary is attached to the bottom of the train cars, and the primary is in the guideway. So a magnetic field is sent down the guideway and it pulls the train along after it. In a way then, the entire length of a maglev track can be considered to be part of the train’s motor. The system that has been described so far is a Linear Induction Motor (LIM). It is so called because the magnetic field in the primary induces a magnetic field in the secondary. It is the interaction between the original field and the induced field that causes the secondary to be pulled along. However, in this configuration, the secondary always lags somewhat behind the moving field in the primary. This lag is a source of energy and speed loss. In a Linear Synchronous Motor (LSM), the lag is removed by attaching permanent magnets to the secondary. Because the secondary is now producing its own stationary magnetic field, it travels down the primary in sync with the moving field—hence the name for this variant of motor (Gieras, 2011). Because LSMs are faster and more efficient, they are the motor of choice in high-speed maglev trains (Lee, 2006).

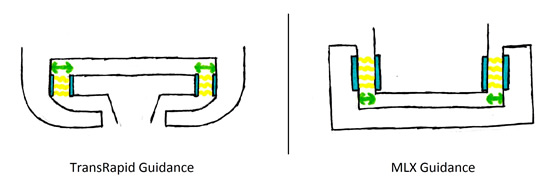

Guidance

Guidance is what keeps the train centered over the guideway. For high-speed maglev, repulsive magnetic forces are used to achieve this (Figure 8). In the TransRapid, there are two electromagnetic rails placed on the train facing either side of the guideway. These rails keep the train from moving too far off course (Lee, 2006). In the MLX, guidance is coupled with the levitation system. The levitation rails on either side of the train are connected to each other. Through this connection, when the train moves closer to one side a restoring force is induced which pushes it back towards the center. Thus the MLX is both levitated and guided at the same time (Lee, 2006).

Figure 8

Guidance system of Transrapid and MLX. Both use repulsive magnets. Source: Author, derived from Lee (2006).

Benefits of Maglev

The most obvious attraction of maglev trains is that they can travel faster than traditional rail trains. The only commercial high-speed maglev, the Shanghai Maglev, is now the fastest train in existence. It travels over 50 mph (80 kph) faster than the fastest high-speed wheel-rail (320-kph Hayabusa, 2013). And it is only the first. The lack of friction between the train and the guideway removes many limits that bound traditional trains. Maglev will only get faster from here (Luu, 2005). There are other, more subtle qualities that also make maglev attractive:

- Longevity: Conventional wheels and rails undergo a great deal of stress over time. They must be replaced and repaired periodically to remain functional. In maglev, there is no contact between train and guideway, so there is substantially less wear-and-tear. The lifespan of maglev parts are appropriately much longer due to this fact (Powell, 2003). Economically, this is quite an incentive, as repair and maintenance are costly and time-consuming activities.

- Safety: It might seem counter-intuitive that these trains are safer, as they travel so much faster than their wheeled counterparts. It is true nevertheless. Maglev trains are near impossible to derail (Luu, 2005). It would take something like complete guideway collapse to part a train from its track. Additionally, weather isn’t much of a problem. Since the trains don’t rely on friction for movement, snow, ice, and rain cause little to no effect (Luu, 2005). Finally, it is easy to elevate the guideways. If the trains are running on tracks ten feet above the ground, there is a smaller chance of collision with an object on its path (Luu, 2005).

- Energy Efficiency: Another benefit of levitation is that these trains don’t lose any energy to friction. This gives them an advantage in efficiency (Wang 2010). Energy consumption is essential to the success of a transportation system. Much of the cost of operating one goes to paying for power. Therefore this edge in efficiency is very important. However, while maglev trains are more efficient, they are currently not substantially more efficient than modern high-speed rail. They do, though, have the potential to be far superior in this category.

- Environmental Impact: Maglev trains can make tighter turns than high-speed rails can. This allows guideways to be built which can navigate terrain much better (Wang 2010). The paths can be engineered to have as little effect on the environment as possible. Guideways also take up less area than rails do (Wang 2010). This further reduces environmental impact. And, as noted before, guideways are easily elevated off the ground (Luu, 2005). Plants and animals alike are safer with the the train traveling above them, and not barreling by right next to them.

- Noise Pollution: When considering a transportation project, noise (within reasonable bounds) isn’t as large a concern as economy or safety. However, noise reduction is still considered a positive feature. Maglev trains are quieter than contemporary trains, so this is another point in their favor (Wang, 2010).

Drawbacks of Maglev

Although there are many upsides, there are still reasons why maglev trains are not being built everywhere. Perhaps the biggest reason is that maglev guideways are not compatible with existing rail infrastructure. Any organization attempting to implement a maglev system must start from scratch and build a completely new set of tracks. This involves a very high initial investment (Coates, 2004). Even though guideways cost less than rails over time (Powell, 2003), it is hard to justify spending so much upfront. Another problem is that maglev trains travel fast, but they might not travel quite fast enough. Countries with high-speed rails already in place don’t want to spend billions of dollars implementing a system that is only marginally better than the existing solution. The market for these trains just isn’t very large at the moment. It is hard to dispute that these trains are superior to standard ones. Regardless, more work needs to be done before it is worth implementing them worldwide.

Electrical Engineering in Maglev

Ever since the steam engine, trains have traditionally been in the domain of mechanical engineers. They were all motors and axles, wheels and engines. However, the introduction of maglev technology has broken that tradition. Developing these trains has required input from a number of different fields other than mechanical engineering, including physics and chemistry. Most importantly, though, it has brought electrical engineers to the table. From the beginning, electrical engineers have been major contributors to developing maglev technology. Eric Laithwaite, an electrical engineer, developed the first linear induction motor, an important and necessary precursor to maglev trains. Hermann Kemper, who many believe to be the father of maglev, was also an electrical engineer. German and Japanese electrical engineers worked to establish the maglev programs in their respective nations. And today, electrical engineers are making the technology better and better so that it may appeal to countries all over the world. Maglev trains have surprisingly few moving parts. They are all about electric currents, magnets, and wire loops. Some important topics to the field are electromagnetic fields and waves, circuit theory, feedback control systems, and power engineering. All these fall under the expertise of electrical engineers. Therefore it is electrical engineers that are needed to solve the biggest problems this technology faces. The trains need to be made faster and more energy efficient. All the while they need to be kept well within boundaries of safety. The guideways need to be made cheaper, easier to implement, and perhaps more compatible with existing rails. The control systems need to be made flawless. All of these issues and more are calling out for an electrical engineer to come unravel their answers.

The Future of Maglev

Maglev technology holds great promise for the future. It has the potential to be a cheaper, faster, safer, and greener form of transportation than we have today. And with the help of some electrical engineers, it will become all of these things. There are possible applications for this technology in anything from intercity public transportation to cross-country trips. There are even proposals to build long underground tubes, suck the air out of the tubes, and place maglev trains inside of them. In this setting there would be virtually no wind resistance, so a train could easily reach speeds exceeding the speed of sound (Thornton, 2007). While it may be a long time before this technology becomes prevalent, it is difficult to deny that it will at some point be prevalent. The advantages are too hard to ignore. As of now there is only one commercial maglev train in use, and it has already eclipsed everything that has come before it. How will this technology evolve and improve as we move into the future? Only time will tell. But it is highly plausible that we now stand at the precipice of a transportation revolution. I, for one, look forward to gliding across the countryside at 300 mph in a levitating box of magnets.

Bibliography

- 320-kph Hayabusa matches world speed record. (2013, March 17). The Japan Times. Retrieved from http://www.japantimes.co.jp/news/2013/03/17/national/320-kph-hayabusa-matches-world-speed-record

- Coates, K., Antlauf, W., & Bernardeau, F. (2004). Fast Track. North American Maglev Transportation Institute. Retrieved from http://namti.org/published-articles/articles/civil-engineering/fast-track/

- Gieras, J., Piech, Z., & Tomczuk, B. (2011). Linear Synchronous Motion (2nd Edition). Boca Raton, Florida: CRC Press. OCLC WorldCat Permalink: http://www.worldcat.org/oclc/526111254

- Lee, W., Kim, K., & Lee, J. (2006). Review of Maglev Train Technologies. IEEE Transactions on Magnetics, 42(7), 1917-1925. DOI: 10.1109/TMAG.2006.875842

- Luu, T., & Nguyen, D. (2005). Maglev: The Train of the Future. University of Pittsburgh Swanson School of Engineering. Retrieved from http://www.teslasociety.com/ttrain.doc

- Powell, J., & Danby, G. (2003). The New Mode of Transport For the 21st Century. 21St Century Science & Technology Magazine (Summer 2003), 43-57. Retrieved from http://www.21stcenturysciencetech.com/articles/Summer03/maglev2.html

- Thornton, R. (2007). The Future of Maglev. Paper presented at the International Conference on Electrical Machines and Systems, Seoul, South Korea. Piscataway, NJ: IEEE. Retrieved from http://ieeexplore.ieee.org/xpls/icp.jsp?arnumber=4412045

- Wang, C., & Zong, G. (2010). A Contrastive Study on Sustainable Development of Maglev and High-Speed Wheel-Rail. Paper presented at ICCTP 2010: Integrated Transportation Systems, Beijing, China. DOI: 10.1061/41127(382)20

- Yadav, M., Mehta, N., Gupta, A., Chaudhary, A., & Mahindru, D. V. (2013). Review of Magnetic Levitation (MAGLEV): A Technology to Propel Vehicles with Magnets. Global Journal of Researches in Engineering: Mechanical & Mechanics Engineering, 13 (7), 29-42. Retrieved from http://engineeringresearch.org/index.php/GJRE/article/view/858

Suggested Links

- Discovery. (2009). Maglev Trains. [Video]. Retrieved from http://www.discovery.com/tv-shows/other-shows/videos/extreme-engineering-season-1-shorts-maglev-train/ and https://www.youtube.com/watch?v=1pXlvIpP

- Thornton, R. (2007). The Future of Maglev. Retrieved from http://www.magnemotion.com/industry-solutions/White_Papers.cfm

- The Northeast Maglev. (n. d.). Retrieved from http://northeastmaglev.com/

- Shanghai Maglev Train (SMT). (n. d.). Retrieved from http://www.travelchinaguide.com/cityguides/shanghai/getting-around.htm