For our senior design project, we are working with the 3D bioprinting company FluidForm. Our goal is create a 3D printed tissue models using their proprietary 3D Printing technique called FRESH (Freeform Reversible Embedding of Suspended Hydrogels). We want to explore a biomimetic way of delivering media to tissue constructs by developing and perfusing through vasculature integrated within tissue scaffold design.

One major issue with large three dimensional tissues is perfusion. In the human body, each of our cells can be found within 100um of a blood vessel. Beyond 100um, the diffusion of oxygen slows down so much, that the cells can’t survive. For 3D tissues, recreating this vasculature is a huge engineering challenge.

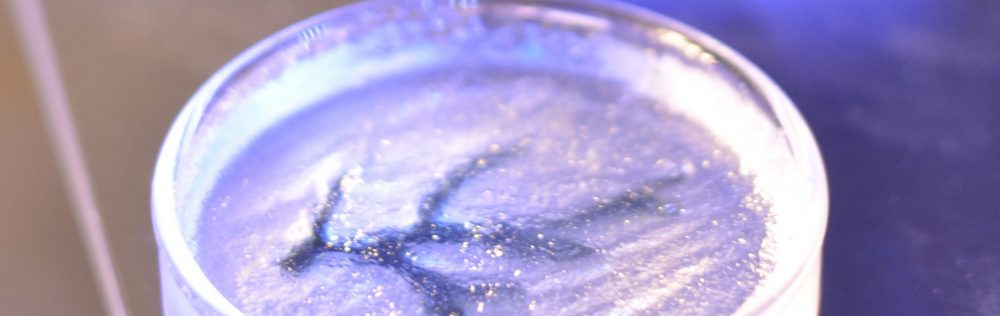

For our project, we are designing the scaffolds to have flow channels similar to that of native vasculature within CAD models. Next, the models are further optimized with G-Code methodologies and fabricated with FRESH 3D printing technology. However, issues with tissue proper sealing, collagen sourcing, printing times, channel pressure, and vascularization generation all play important roles in the success of this project.

To achieve this goal, we have design and test the following:

- 3D print a collagen tissue scaffold using FRESH

- Design a 3D printed flow cell to hold and perfuse blood analogs through the tissue scaffold

- Design a flow loop for the tissue scaffold and flow cell

- Design more complex vasculatures with more biomimetic properties

- Develop vascularization script using appropriate software to procedurally generate complex, biomimetic vasculature

- Recreate, print, and perfuse a vascularized organ