3D Printer Tutorials (5/31/22) –

The purpose of today’s lab section of class was to introduce us to the 3 main types of 3D printers in the lab and expose us to their various capabilities.

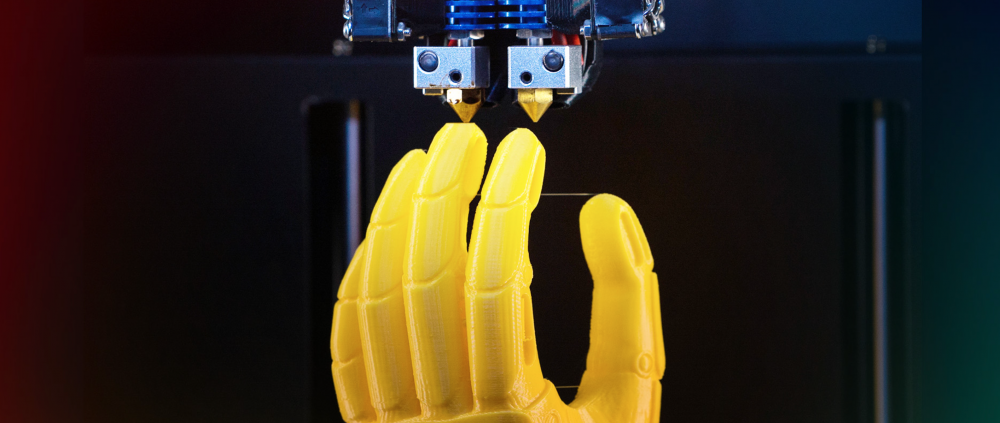

Pictured above is the Bio X 3D bioprinter, which is used primarily by biologists and likely won’t be used much by students throughout this course (expert perhaps if it’s required for an independent final project). The extrusion material is relatively cheap and simple to make, but if used after sitting for several months it will not function properly (as we saw when attempting to print replicates of human ears, above). The printer has three nozzles and a touch screen to change parameters like extrusion speed and pressure in real-time while an object is being printed! The printer also includes a flash drive port that allows us to import the desired STL file.

Another printer we looked at was the Fused Deposition Modeling (FDM) printer, which is the one we’ll be working with most frequently throughout the class. This printer often uses PLA as an extrusion material, which is made by many different companies (Hatchbox and Prusa are the best – quality of PLA is extremely important, as we will learn more when we begin printing) and comes in various colors. These printers read the Gcode generated from an STL file in Prusa Slicer. These files can code for nearly any object you can dream of, all accessible for download for FREE from thingiverse.com (https://www.thingiverse.com/).

The third type of printer we investigated was the Stereolithography (SLA) printer, which uses a laser to trace an object from the bottom up. This printer likely won’t be used often by students, but it’s similar to FDM, except for the fact that it changes chemistry by photocuring the resin extrusion material. Different types of resins are used for different objects, such as more biocompatible resins for mouse cuffs or harder, denser resins that can be used to print hammers and other tools. We also talked a lot about supports and our ability to add/eliminate supports for our printed objects, as well as how to autogenerate the most efficient supports within the 3D printer’s software. Extreme care is needed to be taken with these printers (as with all printers), to take care of the expensive components and especially because Brook has to fix or replace the broken ones, and you don’t want to mess with her.