Stack-able Water Filtration Plant

Introduction & Motivation

Chemical engineers are often very concerned about environmental problems and helping people. For many, becoming a chemical engineer is a fantastic way to help people and the planet! One way to accomplish both of these goals is through water filtration and purification.

Wastewater is produced from many industrial processes all over the world and can harm local waterways if it is dumped without proper treatment. Additionally, people do not have access to clean drinking water in many areas. It is the job of many chemical engineers to develop filters and chemical processes to treat and clean water for people.

Students will work in teams to design a water filtration system. They will be given dirty water and tasked with finding a way to clean it while spending less than $50 and keeping the tower less than 3 feet tall. Students will have the ability to pick between many different types of tubing, filters (coffee filters, activated charcoal, gravel etc.) out of which to build their filtration system. This will help students experience a chemical engineering design challenge with real world applications and considerations.

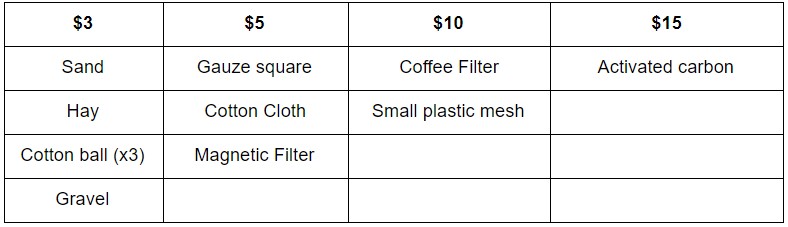

Below are the proposed raw material costs:

Materials

- Schedule 40 1-½” Clear PVC tube cut in 3” sections (diameter ≈ 1.894”)

- Schedule 40 1-½” PVC Couplings

- Laser Cut Acrylic Rings (same OD as PVC) (Top)

- Laser Cut Acrylic slides with holes (same OD as PVC) (Center)

- Magnetic discs with holes (Bottom)

- O-rings

- Ring stands

- Duct tape

- Small plastic mesh

- Cotton cloth

- Gauze Squares

- Cotton balls

- Plastic Cups

- Sand

- Hay

- Activated Carbon

- Water

- Soil and/or coffee grounds (Regular dirt does not filter out well!)

- Iron filings

Procedure

To make a filter, sandwich filter material between Laser Cut Acrylic Rings or Laser Cut Acrylic slides with holes and rest in the coupling. Lay o-ring on top and push 3” section of PVC into coupling.

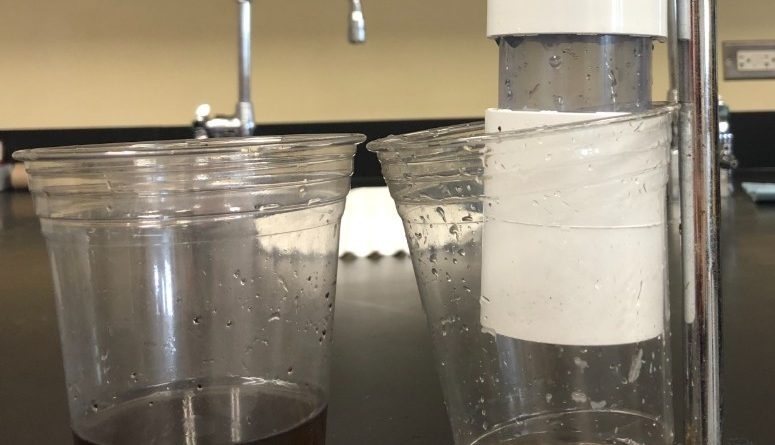

- Present the students with a cup of dirty water to purify. Prepare this by mixing soil/coffee grounds and iron filings into water. Be sure to inform them what is in the mixture, but acknowledge that chemical engineers sometimes do not have this information!

- Have students brainstorm their water filtration tower. Record or illustrate what the levels of filtration are and how much money they’ve used using the table above.

**Tip! Be sure to include a piece of cloth above the magnetic disc before flowing the dirty water. After iron filings directly touch a magnet, they are very difficult to remove!** - Once the tower is ready, duct tape it to a ring stand for extra support, place a plastic cup underneath, and pour in the dirty water! Watch as it flows through a system. This is an important time to highlight that while adding more material between filtering layers could catch more particles, it also has the potential to slow down flow!

**Tip! This activity is typically performed before lunch because it can take a while for water to fully flow through the towers. If students are overzealous with packing their filtration levels, have them clean up their station otherwise and let it sit through lunch!**

Discussion

- Ask students why they think they had a price limit. Use this time to explain that a lot of times a product has to be produced below a certain cost to ensure more people have access to it. (In the case of a water filter, you don’t want it to be prohibitively expensive!)

- What kind of compromises did the students have to make to spend less than $50? (Perhaps they used a cheaper, less reliable filter)

- What kind of improvements could they make if there were no cost limit?

- Did they filter the wastewater more than once to try and get it to be cleaner?