Scaling Up: Final Project

Introduction & Motivation

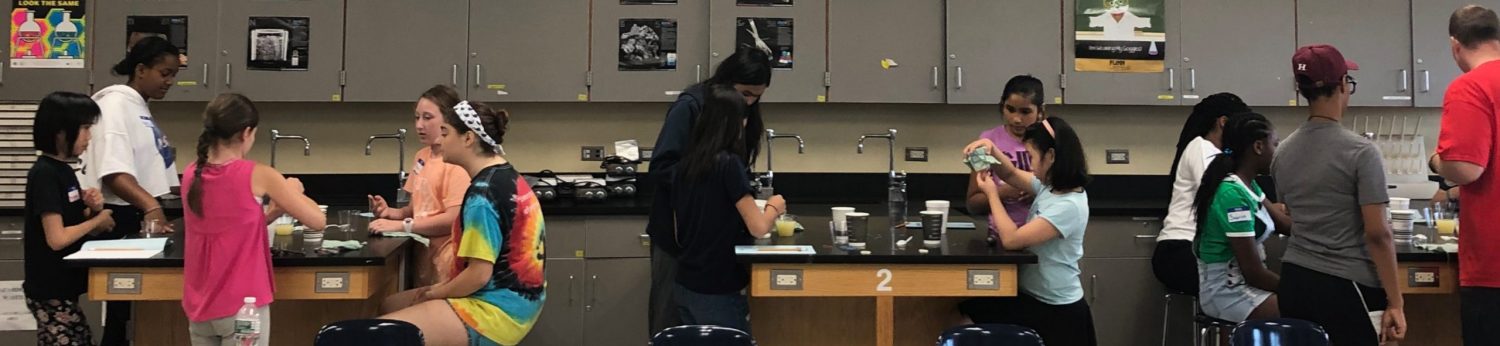

At this point in the camp, the students have learned about many aspects of chemical engineering. The purpose of the final project is to integrate the knowledge gained from the activities throughout the week, allowing students to combine and solidify what they have learned about the types of things engineers have to consider during design.

The final project is based on the Chemical Engineering CEOs theme introduced on the first day of the camp. In this iteration, the students will be asked to plan the entire process of producing a spherified good of their choice so that it can be sold in stores. Using their experience with the Reverse Spherification activity and designing within constraints, students will be given a certain amount of fake money and asked to create/present their idea for using factory machines to produce and distribute their good.

In the brochure provided below, each aspect that could be involved in the factory has an associated cost, operation time, environmental rating, space requirement, and manual labor requirement. Once the students have completed their processes, the total values of these quantities describe how good the process is designed. Maybe your main goal is for the process to be environmentally friendly, so a high cost is not as important. On the other hand, maybe you must work within a strict budget, so you have to pay more attention to the cost. These are just a few considerations engineers have to make when designing a process.

Materials

- Machinery brochures and pictures (see additional resources below)

- Magnetic white boards

- Magnets

- Whiteboard markers & erasers

- Fake money

Procedure

- Show one of the How It’s Made videos listed below.

- Replay the video slowly (on mute) and while it’s playing, draw on board the specific flowchart for that process. Highlight the general process. Explain to the students the importance of planning out the machinery process.

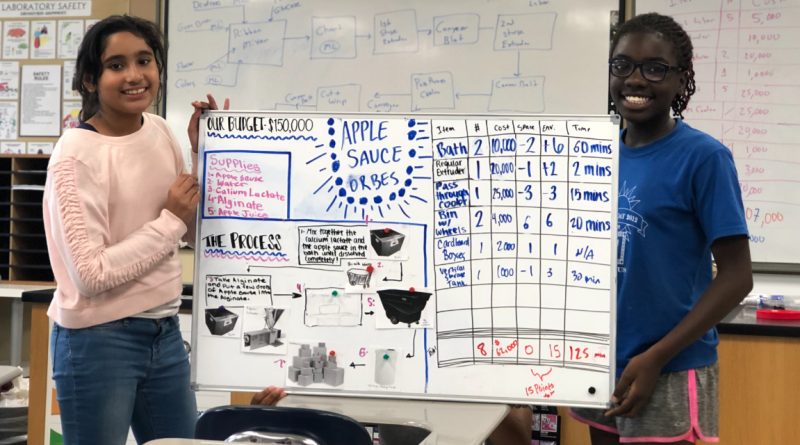

- Give each group of students $150,000 in fake money and the machinery brochure.

- Task the students with making a manufacturing process for their spherified good. Ask the students to try to design a process that requires the least amount of money, takes the least amount of time and requires the least amount of factory space. First, have them come up with a general process for their factory and then allow them to go through the brochure to pick out specific machines. This helps to keep them from getting too caught up in the details of the machines themselves and losing sight of the overall goal.

- Give them the printed out pictures of the machinery they want to use so they can build their flowchart using the magnetic white boards. They can use the machinery in the brochure, or make up their own equipment. Be sure to keep a tally of the various ratings of each machine on the board.

- There are more types of machines than those in the brochure, but price their invented equipment at a higher price. This is because specialized equipment costs more in the real world. Make sure to tell them about the trade offs between costs, environmental effects, lifespan, ease of use, and manual labor.

- Once the students come up with a flowchart, have instructors sit down and spend 15 minutes talking through their flowchart with them. Are they using the most effective machines? Can they improve production time/lessen their environmental footprint?

- Once all groups are finished, they can each present to everyone!

Discussion

- Why is it important to have specific design goals when trying to scale up? (Engineering involves a lot of trade-offs. Sometimes we have access to really powerful and precise equipment, but this can come at a high cost. Sometimes really effective chemical processes involve fairly dangerous materials. In a more theoretical sense, sometimes we can get really accurate answers from our models, but it requires supercomputers or long wait time for programs to finish. Balancing the pros and cons of each piece is one of the most important jobs of engineers for this reason!)

- Are there other goals you would want to achieve from your process? (Fast shipping time, wide distribution, etc.)