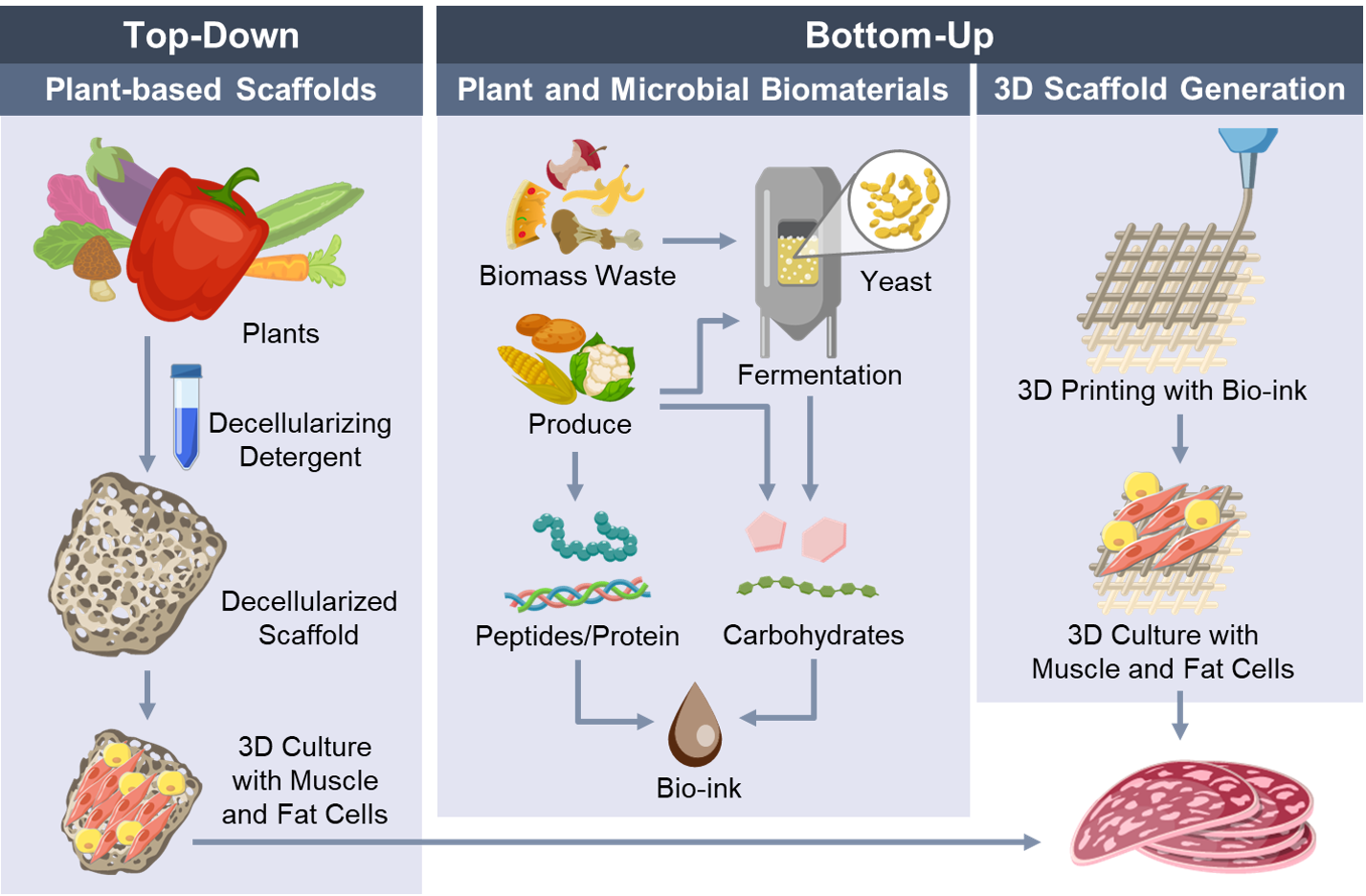

Bottom-Up and Top-Bottom approaches are being applied for developing novel scaffold from plant sources for cultivated meat products. 3D printer and hydrogels will be also applied for specific products with targeted texture and mechanical properties.

We have developed formulas of polysaccharide hydrogel based bioinks that are suitable for extrusion-based 3D printing with sub-millimeter scale resolution. To generalize and speed up the process of bioink formulation and development, we have constructed machine learning models that predict the printability of bioinks based on the hydrogel’s rheological properties and printing performance.

Developed a novel process negative pressure assisted infusion process to combine cells and proteins with 3D scaffolds compositions by decellularization of the plant tissues such as jackfruit tissues and completed characterization of infusion efficiency of both cells and proteins in these scaffolds. This novel process achieved over 70% efficiency in infusion of cells, maintained cell viability during processing and achieved 5 fold increase in the protein content of the plant derived decellularized scaffold

Characterized the role of fungal mycelium in promoting binding of cells and the proliferation. This project was developed in collaboration with David Block’s lab, who is supported by NSF project on Cell Ag.

One student at Virginia Tech (Amiti Banavar) is focusing on developing plant-based scaffold. Bamboo shoots, banana leaf, celery, carrots, aloe vera, and cactus were decellularized and characterized.