Overview

Having built our first car we set out on designing a new one, THR 12. Starting its development from a cardboard frame in 2011, this car was in production from 2011-2012. Using FH 10 as a starting point, we provided it with a fully hybrid powertrain – this time in parallel – along with several additional improvements.

THR 12 Throughout The Years

2011-2012

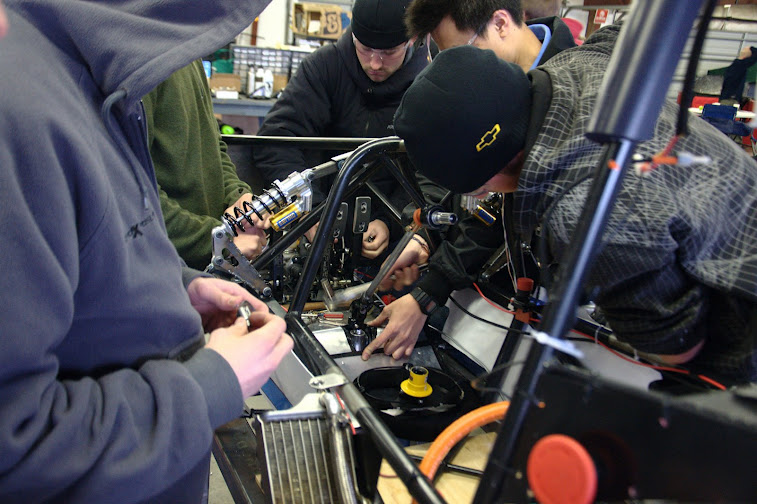

THR 12 lighting fast production window, with the team only working on the car for one year. This was done by working on the car in parallel with finalizing FH 10. For this car, we had the pieces fabricated by an outside party, then welded them in house, working out of our garage in Bray Labs.

Taking what we learned from the FH 10, we were able to design bodywork to improve the aerodynamics of the THR 12. One notable area is that instead of having a nose cone that maximized downforce, we manufactured one to minimize drag in hopes to improve our acceleration.

The newly designed areo package however was just one area of improvement. We switched from lead acid to lithium polymer batteries to increase our energy-weight ratio and also switched out our engine for a more powerful one. The new parallel drive configuration also allowed us to implement rear wheel regenerative breaking. With these improvements we were able to once again enter the Formula Hybrid+Electric competition in 2012.

Car Stats

| REGEN BRAKING | Rear Wheel |

| DRIVE CONFIGURATION | Parallel |

| ENGINE | Husqvarna TXC 250 |

| FUEL TYPE | Gasoline |

| GENERATOR | N/A |

| DRIVE MOTOR | Oxford YASA DD500 |

| ACCUMULATOR | Kokam Lithium Polymer Batteries |

| WEIGHT | 455 lbs |

| UNIQUE FEATURES | Electric Shifting, CAN-Based Onboard Computer, CFD Optimized Bodywork |

Images