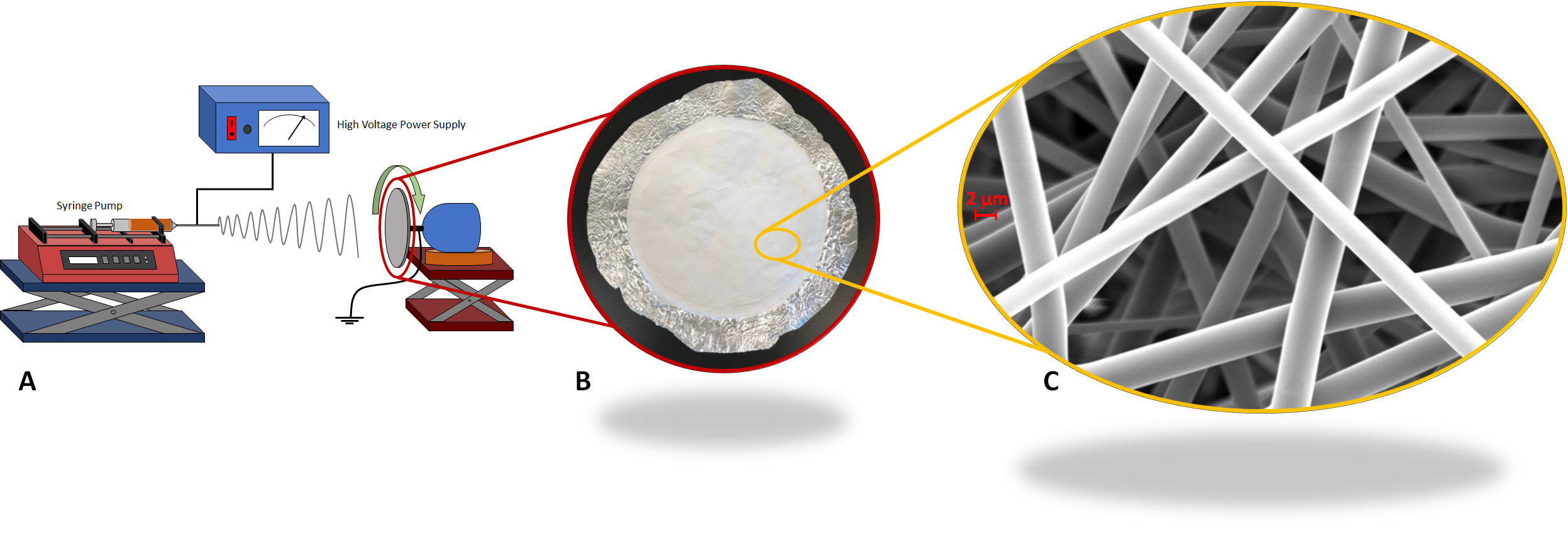

A.) Schematic of our electrospinning set up. A syringe connected to a high voltage source is loaded into a syringe pump for controlled flow. Across from the syringe is a grounded collecting drum where the fibers land. B) Picture of an electrospun fiber mat as it lands on the collector. C) SEM image of a fiber mat showing that the mat is comprised of micron size fibers.

One of the main research focuses of the Cebe Research group is in the study of electrospun polymer nanofibers. Electrospinning is a processing technique where a polymer can be shaped into fibers that can range in diameters on the order of nanometers to micrometers. Electrospinning starts by either dissolving or melting a polymer so that it becomes a viscous fluid. This polymer fluid is then loaded into a syringe that can pump the solution out at a controlled rate. The syringe is supplied with a high voltage, and is aimed at a grounded collector. The high voltage combined with the grounded collector creates a strong electric field which exerts a force on the polymer fluid. At the very tip of the needle the electrostatic force from this electric field is so strong that it overpowers the surface tension and viscosity of the polymer solution, and pulls a thin ribbon of polymer off the tip. As the ribbon flies through the air ejecting solvent, it separates into ever smaller fibers that eventually collided and collect with the grounded collector, leaving a mat of nanometer to micrometer diameter fibers.

Our research interest in electrospun fibers lies both in the potential applications of the fibers as well as the effect that electrospinning has on the crystal structure and chain confinement of the polymers. Electrospun fibers have an extremely large surface area to volume ratio, making them good candidates for catalysis. If a biocompatible polymer is used, electrospun fibers are a good substrate for drug delivery, targeted cell growth, or tissue repair. The porous nature of an electrospun fiber mat makes them a natural choice for filtration applications, and the choice of polymer allows for further tunability in this regard. By nature of liquifying the polymer, electrospun fibers can very readily be made into nanocomposites by inclusion of nano-fillers such as carbon nanotubes, graphene, or nanoclay. On the fundamental properties side, polymers confined to such small volumes leads to many interesting effects, such as chain confinement, and preferential crystal phase formation. Electrospun fibers on the nanoscale offer the potential to investigate heterogeneous vs homogenous crystal nucleation in a material as well.

The Cebe Research Group has an in-house electrospinning set up for creating our very own electrospun fibers, as well as a scanning electron microscope for direct fiber imaging. The fibers are further characterized using X-ray diffraction, infrared spectroscopy, thermogravimetry, slow and fast scanning calorimetry. Here are a few recent publications on electrospun fibers from our group (Published 169, 168, 155, Awaiting Publication 173, 172).