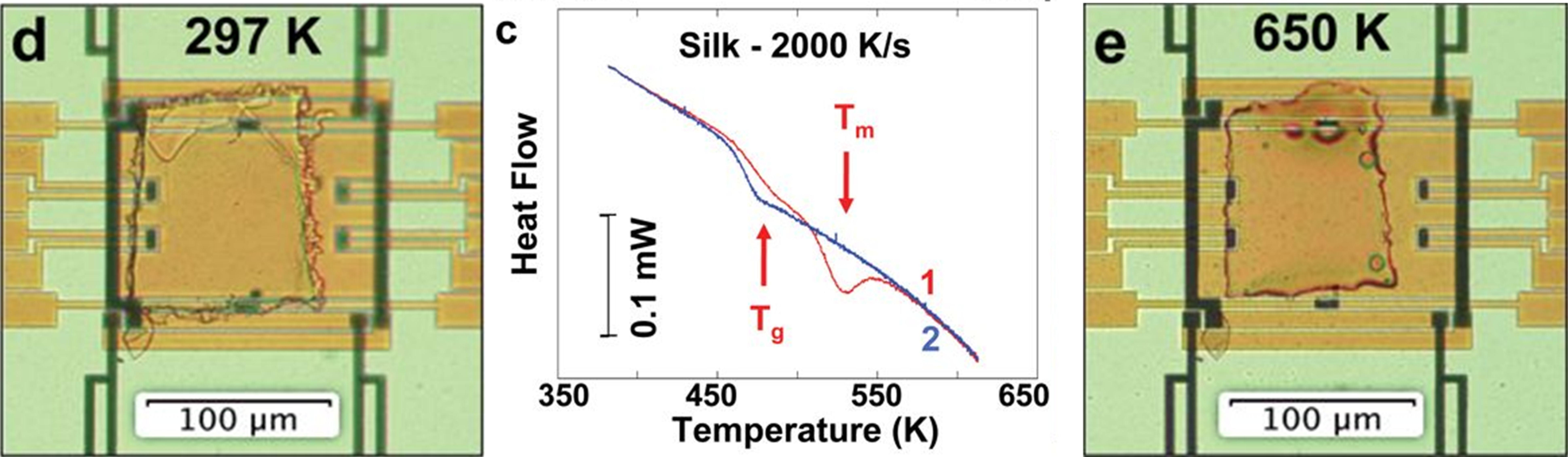

From Publication 135, a typical fast scanning experiment performed at 2000 kelvin per second on a reconstituted film of bombyx mori silk. From left to right, d) silk film at room temperature prior to heating, c) heat flow curve with the film heated (red curve), cooled (not shown), and reheated (blue curve) at 2000 K/s. Initial heating shows the glass transition and beta sheet crystal melting, while the reheat shows only the glass transition. e) Silk film after the experiment shows no signs of degradation!

One of the most important parameters in calorimetric experiments is the heating or cooling rate. A slow heating or cooling rate is useful for determining and identifying certain features in the heat capacity such as enthalpic relaxations or ageing endotherms. A typical DSC will heat or cool at a few degrees per minute. At the other end of the spectrum, if a material is heated or cooled fast enough, certain transitions can be bypassed due to the material not having enough time to arrange itself. Even more tantalizing is the possibility of heating a material so fast that it can be heated to temperatures without inducing degradation, when normally the material would become a lump of carbon. The tricky caveat is that this would require heating or cooling rates on the order of 10s to 1000s of degrees, per second. Trying to get a normal DSC to access these rates will at best lead to thermal lag in the sample, or just no signal at all.

The solution to this problem was the development of fast scanning chip calorimetry, designed by the group of Professor Christoph Schick of the University of Rostock in Germany. By using samples that are on the order of nanograms, and with dimensions of 10s of microns, a material can be heated and cooled on the order off 1000s to 10,000s degrees per second. In collaboration with Professor Schick, our group has used fast scanning calorimetry (FSC) to study the fundamental thermal properties of materials such as poly(vinyl alcohol), bombyx mori silk, melt electrospun poly(ether ether ketone) fibers, and many other materials. We maintain an active collaboration with Professor Schick’s group, and send our graduate students to Rostock to utilize the FSC there.

A) Photo from a recent visit to Rostock (May-June 2018). From left to righ, Yeong Zen Chua, Evegeny Zhuralev, Rui Zhang, Amir Abdelaziz, Dmitry Zaitsev, Andrew Clark, Nelaka Govinna, Professor Chrsitoph Schick. B.) While in Rostock graduate students Andrew Clark and Nelaka Govinna were included in the Physics Department photo commemorating the 600th anniversary of the founding of the University of Rostock (it’s up to you to find them!). C.) November 2018: (From left to right) Andrew Clark, Nelaka Govinna, Professor Cebe, and Professor Schick at the 2018 MRS meeting after Nelaka’s talk.