SETUP AND SAFE OPERATION

-

- Before drill pressing, make sure to center punch with a manual hammer or an automatic center punch (DO NOT hit automatic center punch with hammer)

-

- Mark the placement of the hole with the scribe and place center punch at the mark and press down

-

- To find the right drill bit size, check the poster and also make sure that the drill bit you select is actually the one you want (most drill bits are labeled)

-

- Turn light on next to the drill press

-

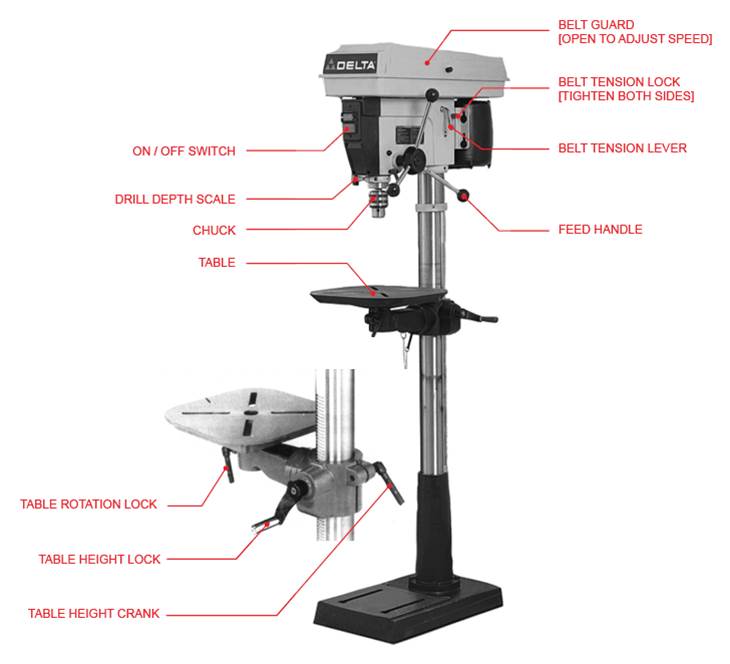

- Use the chuck to insert an appropriate drilling bit — make sure that the flute of the drill bit is not in the chuck

-

- Use the chuck key to tighten the chuck, and hold onto the drill bit — BEFORE turning on, rotate the chuck with your hand to know it is running true; use the chuck key to ensure chuck is tight and remove chuck key

-

- Use the parallel bars to keep piece level and clamp down the piece with one hand on the top of the piece; if piece is too small, take out the parallel bars

-

- Move the x and y axis (which moves the piece) to put the bit at the center punch indent

-

- Rotate the bit to make sure it is in the middle — there should be no deflection

-

- Use cutting oil (tap magic) on the piece and the bit

-

- Turn on machine and lower the bit into your piece, providing consistent pressure while relieving pressure every few seconds to breakup chips

-

- Use a brush to clean off the worktable and vacuum before the next user begins operation

- Unclamp piece and take out the drill bit using the chuck key while holding the bit and put the bit away

CLEANUP

- Make sure bits are returned to their proper location

- Clean table, floor, and surrounding work area

- Turn off the light

NOTES

- Select appropriate spindle speed after starting the drill press

- Don’t force the drill too hard-let the tool do it’s job

- Drilling should never produce smoke; if this happens use spray coolant, reduce the spindle speed, clear out the excess chips, or get a sharp bit

- Don’t touch your piece until the spindle has come to a complete stop

- Failing to clamp your piece properly will cause it to spin around dangerously, this is nicknamed a “merry-go-round”