Working on a project at Bray

Bray’s resources are accessible to everyone in the Tufts community. Mechanical Engineering students, faculty and staff will be prioritized.

The safety quiz is required for all users to work at Bray and gain access to green zone hand tools.

Training is required for the use of yellow and red zone equipment. Appointments can be made for these trainings.

Please review the shop safety rules to ensure a safe environment for all users.

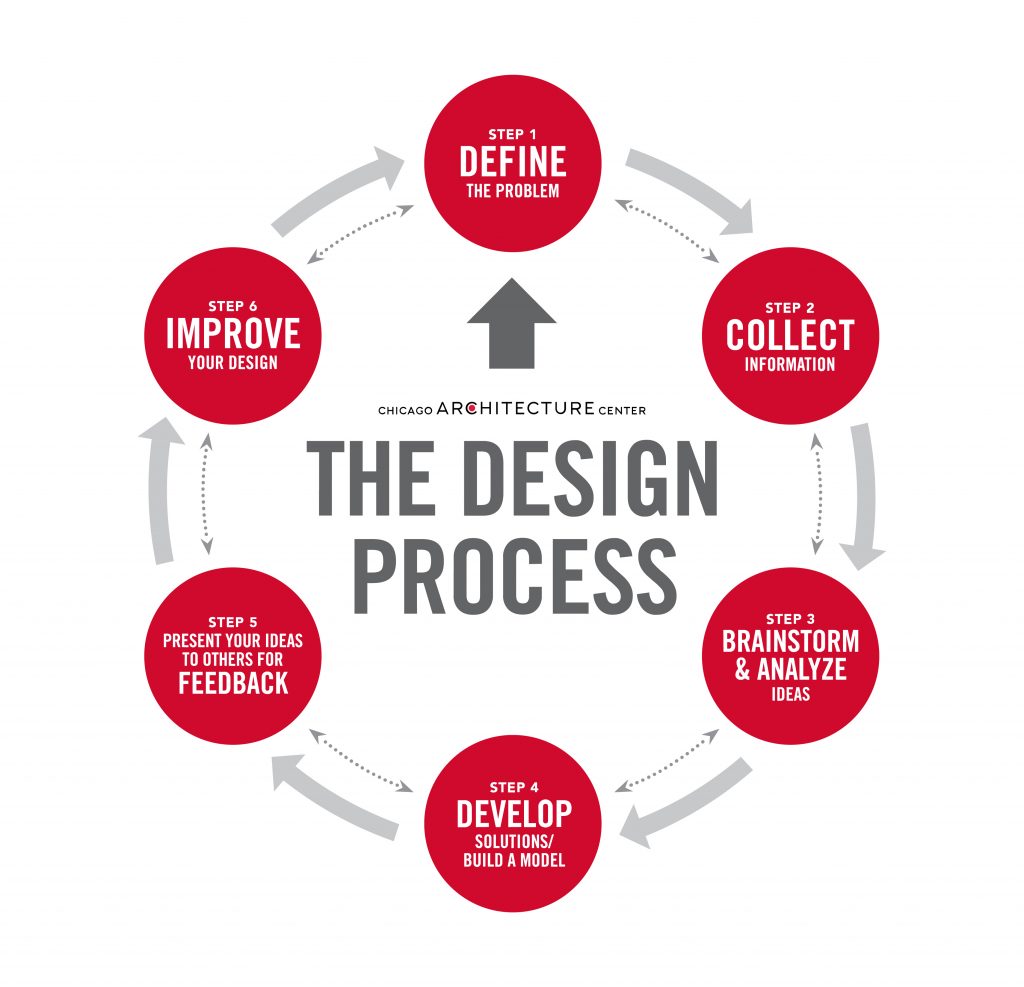

Being successful at Bray: developing an idea into a product

- Define a problem

- Focus on challenges, goals and opportunities for improvement

- Collect information/Research everything about the problem and more

- Gather a list of design requirements (examples include: function, weight, and size)

- Brainstorm & analyze Ideas

- Sketch as many different designed solutions as you can think of, reserve judgment

- Work on a process of elimination once you have a few ideas drawn out. Find flaws in designs that may prevent the goal from being met.

- Tip: The more designs you have the more likely you are to find the one that is just right for your application. Make a range!

- Resources: Use our How to Sketch Design Resource and work with Bray Staff!

- Develop solutions/ build a model

- Learn about what processes, in the shop, are valuable to reach your prototype goals

- Bray offers lots of materials and methods for making prototypes. If you need help, please visit the Shop or contact a staff member.

- Highly recommended: bring a drawing or sketch if you plan to use the machine shop’s hand tools (Green Zone) or power tools (Yellow Zone)

- Resources: People at Bray, Available materials and recommended vendors, digital design programs for using computer controlled machines, equipment, assisted fabrication for using advanced equipment, Dieter Rams’ 10 Principles of Good Design, Nielsen’s 10 Principles, Norman’s rules from Design of Everyday Things

- Present your ideas to others for feedback

- Improve your design by testing your prototype, analyze points of failure, begin new iterative cycle

- Helping you with sketching

- Training you on the machines

- Helping you decide fabrication methods and materials

If you need help, please visit the Machine Shop to meet student & staff workers.

Resources

People at Bray

Available materials and recommended vendors

Digital design programs for using computer controlled machines such as the 3D printers, CNC router, CNC mill and laser cutter.

Assisted Fabrication for using advanced equipment (CNC router, CNC mill and Markforged 3D printer)

- Complete the safety quiz

- Sketch out or digitally define your design solution

- Have a plan for the fabrication method you would like to use or learn about

- Complete any prerequisites for using the equipment

- Sign up for a training or use our assisted fabrication process

- Make sure you wear proper attire

- If you are visiting the machine shop, visit the webpage for the shop

- Follow the design process

- Explore multiple ideas

- Make a sketch, digital design or a low-fidelity prototype (example: cardboard prototype)

- Have a working plan

- Use the resources we offer, such as trainings and workshops

- Work on improving your design after the first iteration

- Ask questions when you need help