Laser Cutter

Trotec Speedy II 40 Watt Laser

&

Trotec Speedy 400 120 Watt Laser

About the Tool: Subtractive manufacturing. Cuts and etches material selected to match the path given.

Location: The Shop

Access: Laser Cutter and Hand Tools (“green zone”)training required.

File types: .dxf, .dwg, .eps, .ai (adobe illustrator), .pdf

Build size: 39in x 24in

Layer thickness: 0.254 mm (0.01 in.)

XY Accuracy: .005 inch per inch of build OR .0015 (whichever is larger)

Materials:

| Category | Allowable Materials | Restricted Materials |

|---|---|---|

| Wood | Solid wood Plywood MDF Tempered hardboard Hardwood [engrave only] |

Pressure-treated Stained Painted wood |

| Paper | Chipboard Museum board Mat board Butter board |

Corrugated cardboard [fire hazard] Coated paper |

| Plastics | Acrylic (up to 1/4 inch) Kapton tape (Polyimide) Mylar (Polyester) |

ABS [releases cyanide gas] Carbon Fiber Delrin [releases formaldehyde] Fiberglass HDPE [melts, hard to cut] Nylon PETG [melts] PVC [releases chlorine gas] Polycarbonate / Lexan [fire hazard] Polyethylene (PE) [melts] Polypropylene (PP) [melts] Vinyl [releases chlorine gas] Styrene Teflon |

| Foam | None | Fire hazard |

| Glass + Metal | Engrave only | |

| Leather | None | Leather [Offensive Smell] |

| Rubber | None | Rubbers [may release chlorine gas] |

| Textiles | Aramid Cotton Fleece Felt Lace Polyester Silk Synthetic & technical textiles |

|

File Types

The software accepts any 2D drawing. For cutting, the drawing must have vector lines with a stroke of .001 and pure red.

Please visit the Design Programs webpage for software recommendations.

Physical Setup

- Turn on Trotec Speedy II and filtration system

- Use the focus tool and buttons on the machine to focus the laser.

Digital Setup

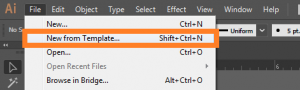

- File -> New from Template… -> Bray Laser

- Select “File -> Place…” then select your file. This will insert your drawing into the Bray Laser template.

- To cut

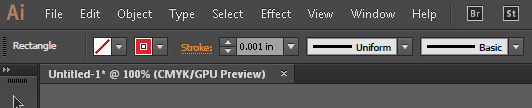

- Lines must have a .001 inch stroke and be RGB Red:

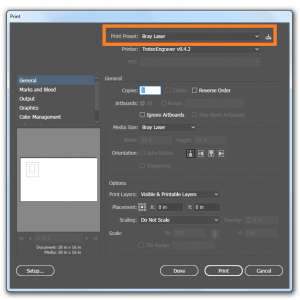

- Select File -> Print

- Select Printer Preset: “Bray Laser”

- Job Control Program will open

- Drag your file onto the bed and position where you want it to be cut

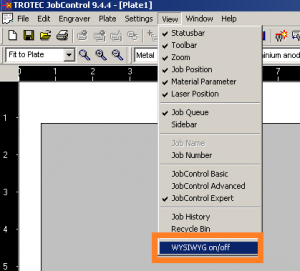

- Go to view -> WYSIWYG to view drawing

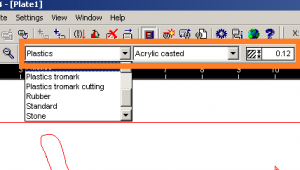

- Select material and enter thickness

- Connect to laser cutter

- Select Play

Safe Operation

- Machine must be monitored while in use.

- Wait until the light on the fan button turns from yellow to green to indicated it is safe to open the top because air filtration is completed.

Cleanup

- Remove your material and all debris.

- Throw excess material in the trash.