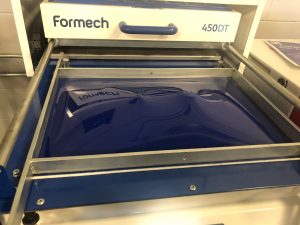

Formech 450DT Vacuum Former

Formech 450DT Vacuum Former

About: Heats a sheet of plastic to a malleable temperature and stretches it to the shape of the given mold using a vacuum.

Location: Machine Shop

Access: Vacuum Former training required. Visit the Machine Shop to request training.

Mold Material: plastic (such as 3D printed), foam, wood, or metal. Mold must have draft angles.

Forming Area: 430 x 280mm / 17 x 11″

Sheet Size: 450 x 300mm / 18 x 12″

Max Material Thickness: 6mm / 0.25″

Material Type: HIPS, ABS, PETG, Styrene, Polyethylene (foam)

Setup

Do not place anything on the top of the heater and/or its housing.

- Turn on machine with switch on lower left side.

- Use large level to raise stage.

- Place mold on stage.

- Lower stage.

- Preheat by pressing the wave icon followed by the play icon.

- Wait until warm. Heater should feel warm when place hand nearby. DO NOT TOUCH THE HEATER.

- Place plastic sheet on gasket frame and clamp.

Safe Operation

- Pull head forward.

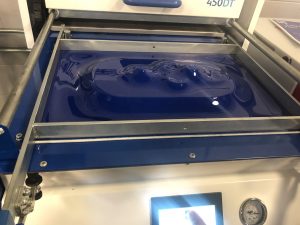

- Clock will begin. Wait until the plastic is evenly droopy (about 2 minutes).

- Push head back. Move stage up.

- Select the middle option to apply a vacuum downward.

- Select the rightmost option to push air upward into the mold.

- Wait for both the finished part and the mold to cool before handling.

Cleanup

- Turn off the heater.

- Turn machine off with switch.

- Remove part and mold from the bed.

- Separate plastic part and mold.