Markforged Onyx 3D Printer

Markforged Onyx One 3D Printer

Location: 3D Printing Lab

Access: Part Request or Free Hours (Mon, Wed, Fri 10-5) 3D Printer training required for Free Hours.

File types: .stl

Materials: Nylon and fiberglass/carbon fiber

Build size: 320 mm x 132 mm x 154 mm (12.6 in x 5.2 in x 6 in.)

Layer thickness: 0.1 mm (0.004 in.)

XY Accuracy: unknown

Pro: Specializes in continuous fiber reinforcement (CFR) which is comparable in strength to Aluminum.

Con: Can only print with Onyx branded materials.

Setup

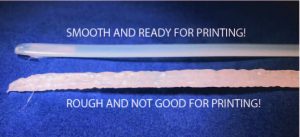

- Run purge prints to ensure nylon prints correctly.

- On the screen of the 3D printer, select menu (on the upper right corner)-> utilities-> test prints-> wet plastic purge print

- Once the purge line comes out smoothly, begin setup for print.

- Spread Elmer’s glue on the part of bed where you will print.

- In the Eiger software, send your print directly to the 3D printer or add your print to the queue.

- Watch the machine for at least the first 30 minutes of your print to ensure that the printed material adheres to the bed and the object is printing correctly.