Sheet Metal Bender

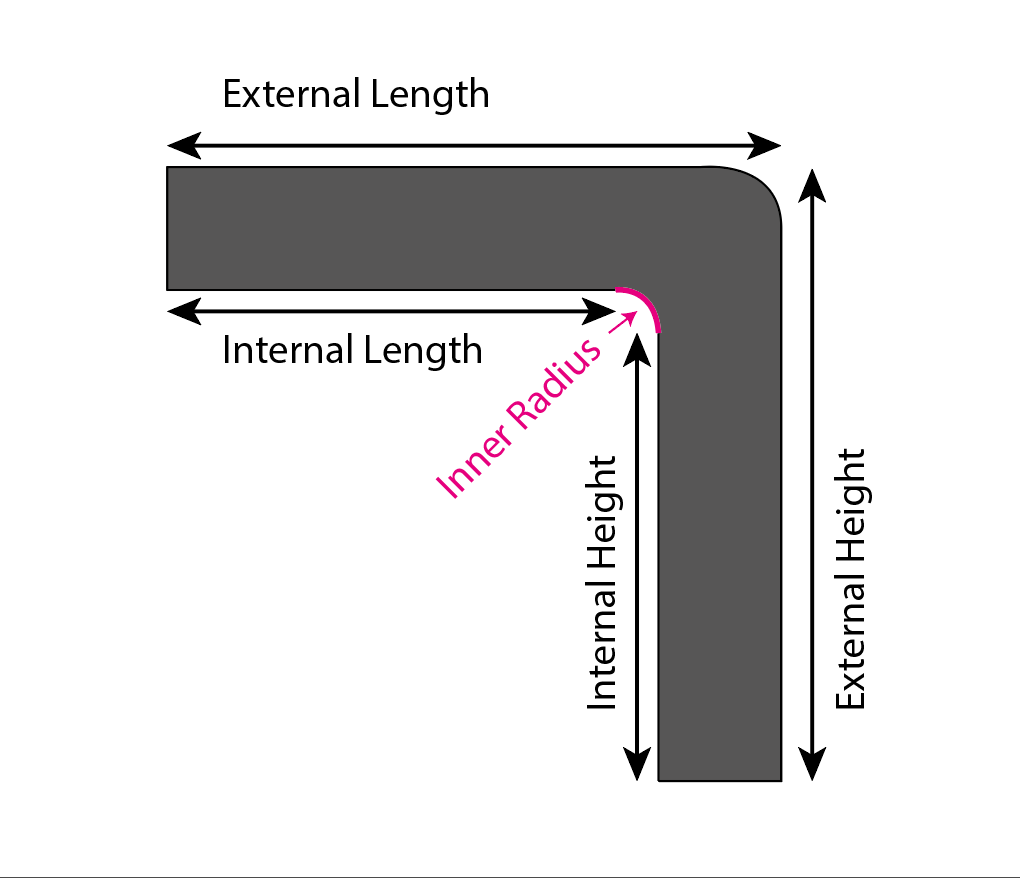

About the Tool: Bends sheet of metal to create a rounded corner based on the physical setup used.

Location: Machine Shop, Room 114

Access: Sheet Metal Bender training required. Visit the Machine Shop to request training.

Materials: Sheet metals

Accuracy: Accuracy varies.

Design Considerations

Physical Setup

- Mark beginning and end of bend allowances on part before starting.

- Line up beginning of bend allowance with separation in metal bending platform.

- Line up end of bend allowance with clamp. Add C clamps to keep part secure.

- Put levers in place.

- Pull toward you to complete the bend (this may require another person to help complete).

Safe Operation

- Work with pieces that have already be deburred.

- If bending allowance used is too small the clamps can slip or the piece can break.

- Ask for help if you cannot perform bend alone.

Cleanup

- Unclamp and remove workpiece

- Put C clamps back

- Place bar clamp back on meta bender platform