Instron Electropuls E3000

The Electropuls offers both linear and rotary motion which can be applied through a wave function with a variety of shapes and a range of frequencies. As a result, it can be used for precise fatigue testing of tensile/compressive loads, torsional loads, and 3-point bending. The linear and rotary components of the Electropuls can be programmed separately, allowing you to test materials under varying loads when a constant torsion is applied (or vice-versa).

Location: Bray Lab Room 107

Access: Please contact Bray staff to schedule

SAFETY: Proper machine shop attire should be worn at all times by the operator. Do not touch the machine as it is performing a test

What are the major differences between Instron Electropuls E3000 and Instron 5800R Test System?

Both Instron machines offer linear tension, compression, and 3-point bending testing. Instron 5800R is specialized in static testing and is not good at handling any torsional load. The load cells of Instron 5800R could be damaged under torsional load easily. On the other hand, Electropuls E3000 offers both linear and rotary motion through a wave function with a variety of shapes and a range of frequencies, and as a result, very precise cyclic loading and torsional loading tests can be performed.

Besides, the loading capacity of the two machines are also very different. the Instron 5800R machine can deal with very large tensile/compressive static loading (up to 100 kN), but the Electropuls E3000 can only go up to 3 kN under dynamic loading (as the name suggests,) and 2.1 kN under static loading.

Machine Limits Table

| Parameter | Limit Range |

| Compressive Force (Dynamic) | 3 kN |

| Tensile Force (Dynamic) | 3 kN |

| Compressive Force (Static) | 2.1 kN |

| Tensile Force (Static) | 2.1 kN |

| Position | +/- 30 mm |

| Rotation (single revolution mode) | +/- 135° |

| Rotation (multi revolution mode) | +/- 5760° |

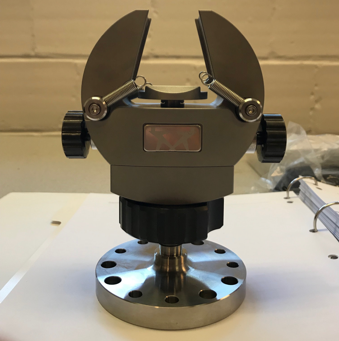

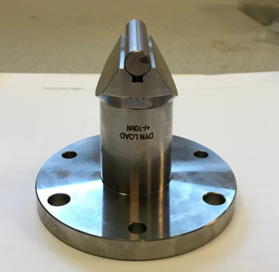

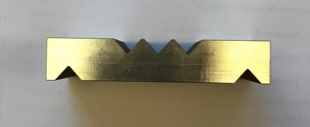

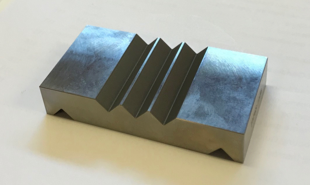

Fixtures

How Does the Instron Test System Work?

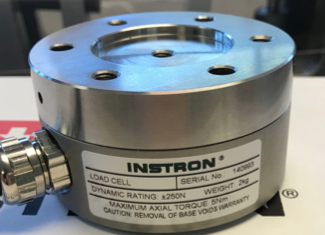

A load cell is installed in the top of the load frame, and a material specimen is held in place inside using fixtures and grips. Once a testing protocol has been initiated, the center crosshead will travel vertically or rotary, propelled by Head (red) located on the upper part, while the load cell mounted onto the Base stays stationary.

DO NOT TOUCH THE MACHINE AS IT IS MOVING. The speed, distance, and direction of travel is determined by the testing protocol which has been programmed by the operator beforehand. The Instron E3000 is capable of performing tension, compression, torsional, and 3-point bend tests.