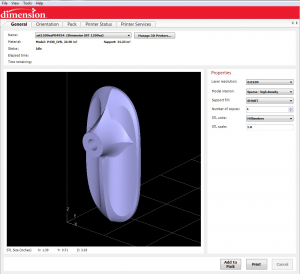

Dimension 3D Printer

Stratasys Dimension 1200es

About the Tool: Additive manufacturing. Prints a 3D part layer by layer.

Location: The Shop

Access:

Dimension and Fortus 3D Printer training is required. Prerequisite: Desktop 3D printer training.

File types: .stl

Materials: ABS and soluble support material

Bray Lab has a Dissolving Bath for removing the support material

Build size: 254 x 254 x 305 mm (10 in x 10 in x 12 in.)

Layer thickness: 0.33 mm (0.013 in.) or .254 mm (.010 in.)

XY Accuracy: .025mm (.001 in)

Stratasys material canister and cartridge shelf life and handling

Setup

Digital Setup

- Select File -> Open STL to import a design.

- Double check part size’s outside dimensions are correct by matching with STL size (bottom left corner)

- Set the model interior

- Sparse – low density (medium strength, 25% – 30 % fill, quick print)

- Sparse – high density (high strength, 75% fill, medium print time)

- Solid (highest strength, 100% fill, slow print)

- Select ‘Orientation’ tab to properly orient part to limit necessary support material

- Press ‘Add to Pack’

- Select ‘Pack’ tab

Safe Operation

- Select a tray and review the tray to select the best position for the part

- Position model in middle of bed

- Press ‘Print’

- Watch the machine for at least the first 30 minutes of the print to ensure the printed material adheres to the bed and the object is printing correctly.

Cleanup

- Take the tray out of the machine to remove your 3D print

- Place tray back in machine

- Throw excess material in the trash.

Removing Support Filament from Bed

- Leave filament on bed as is after removing part from bed

- Attempt to remove filament with hands

- Scrape off with scraper- should come off in one big piece

- Sand if necessary and clip off support filaments