Fortus 3D Printer

Fortus 360mc

Location: 3D Printing Lab

Access: Part Request or Free Hours (Mon, Wed, Fri 10-5) 3D Printer training required for Free Hours.

File types: .stl

Materials: ABS and soluble support material (Bray Lab has a Dissolving Bath for removing the support material).

Build size: 355 x 254 x 254 mm (14 in x 10 in x 10 in)

Layer thickness: 0.254 mm (0.01 in.)

XY Accuracy: .005 inch per inch of build OR .0015 (whichever is larger)

Infill Percentages: Sparse = 20%, Sparse-Double = 40%, Solid = 95%

Stratasys material canister and cartridge shelf life and handling

Setup

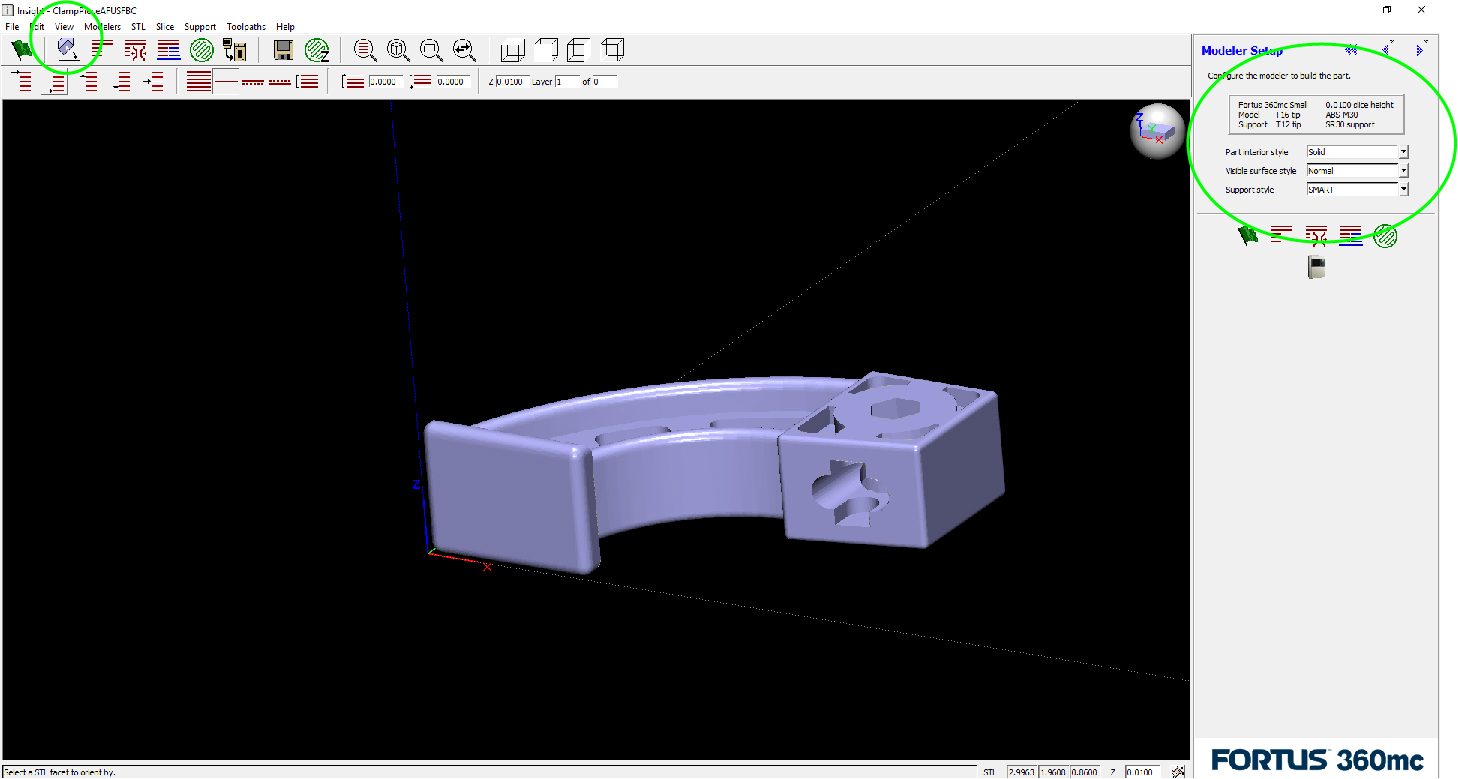

Slicing STL – Step 1 of 3

- Open Insight Software

- Select File -> Open to import STL File.

- Double check part’s outside dimensions are correct (bottom left corner)

- Select a Modeler Setup

- Part Surface Style:

- [recommended] Sparse – low density (medium strength, 25% – 30 % fill, quick print)

- Sparse (Double Dense) – high density (high strength, 75% fill, medium print time)

- Solid (highest strength, 100% fill, slow print)

- Visible Surface Style: Normal

- Support Style: SMART

- Part Surface Style:

- Select STL –> Automatic Orientation to orient part with least amount of support material (this will create the fastest print time)

- Select the green Flag button under Modeler Setup once again. This will generate a CMB File in your folder.

- Select the Build icon

Control Software – Step 2 of 3

- If Control Software does not automatically open after selecting the Build icon manually open the Control Center Software and import your CMB File using File -> Insert CMB.

- Place your part on the bed in the correct position.

- Select Build Job.

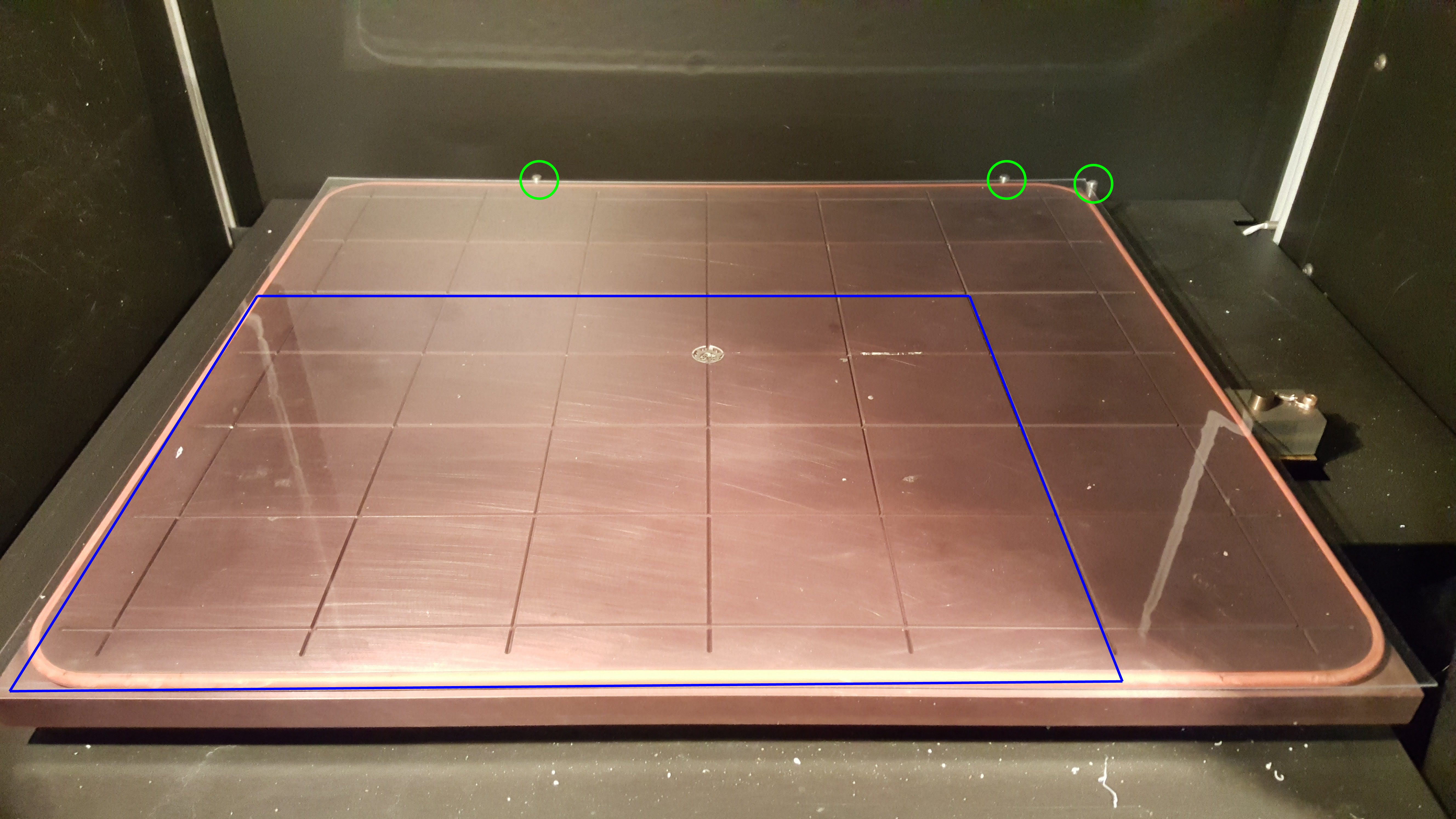

Hardware Setup – Step 3 of 3

- Make certain that that the plastic sheet is aligned with the tabs on the upper right corner and the top edge.

- The blue square below represents the build space available on the Control Center Software. This represents the position where the part will be built.