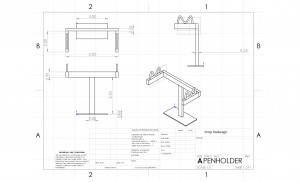

We have finished sketching out our ideations and have now moved on to creating our prototypes on Solidworks. Our pen holder model looks like this:

Before we begin the fabrication process we want to try orienting the pieces in different ways just to see if we can create a more aesthetically pleasing model. We will then begin making protoypes with whichever design we prefer. Also, we are prepared to make some changes to our model after fabricating, because the fabrication process will reveal some detail flaws that can only be noticed with the physical model. For example, while we have a sense of the amount of time it takes to build this, actually building it will obviously give us a better time approximate and we can make changes on the design depending on whether it takes too long or too short to build. Fabricating will also give us a better sense of material cost and if the structure will have proper weight distribution and will stand sturdy and upright.

A few things to mention with this design are that we intend to use the DIWire machine to create the support mechanism which directly suspends the pen. We spent time working with the DIWire machine to figure out the minimum segment length needed for a bend in the wire and the maximum angle that the wire can bend. We discovered that there needs to be at least approximately 3/4″ of material between two bend points and the maximum bend angle is roughly 55 degrees. This knowledge was helpful because it allowed us to draft a better and more precise model that fit the maximum parameters of the DIWIRE.

In addition, we spent time making different configurations of this model on Solidworks. By that, we mean that we uploaded the same exact parts into an assembly but tried different rearrangements of those parts. We are still working on making the second configuration of the pen holder, as it has taken some time to learn the nuances of Solidworks, so we aren’t able to upload a drawing on this post but the other model essentially deals with rotating all of the aluminum 1/4″ stock pieces 90 degrees so they lie horizontal on the main support bar, instead of vertical. We liked this design feature, and we will continue forward with the design we prefer or we may even just fabricate both models to compare.