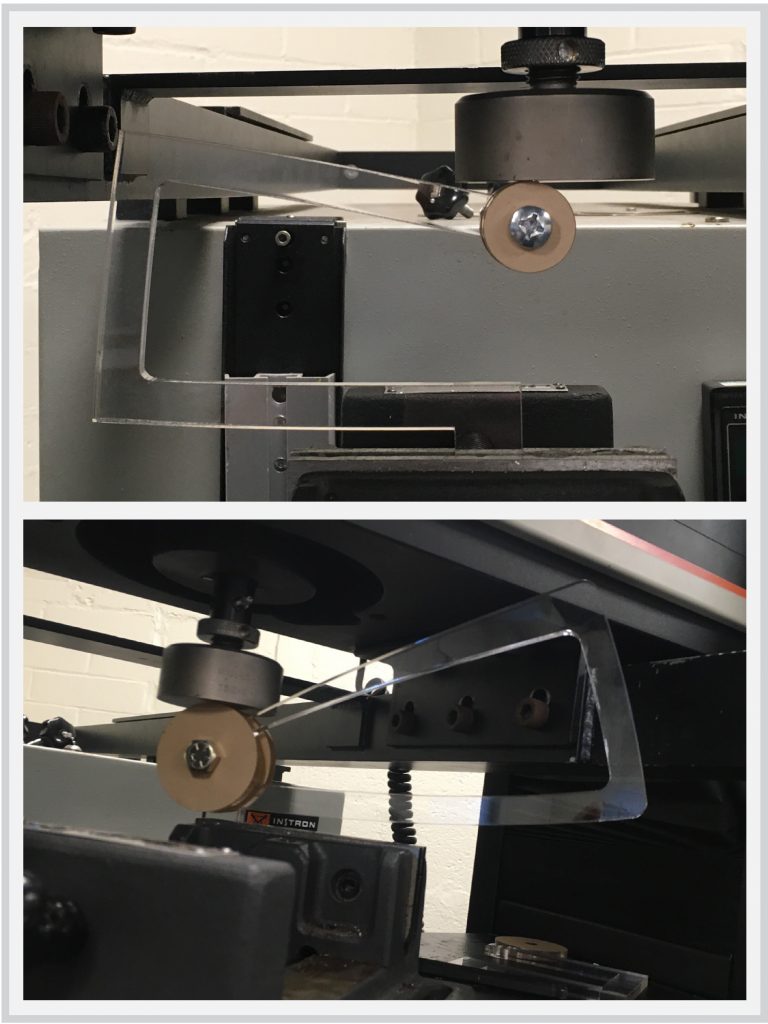

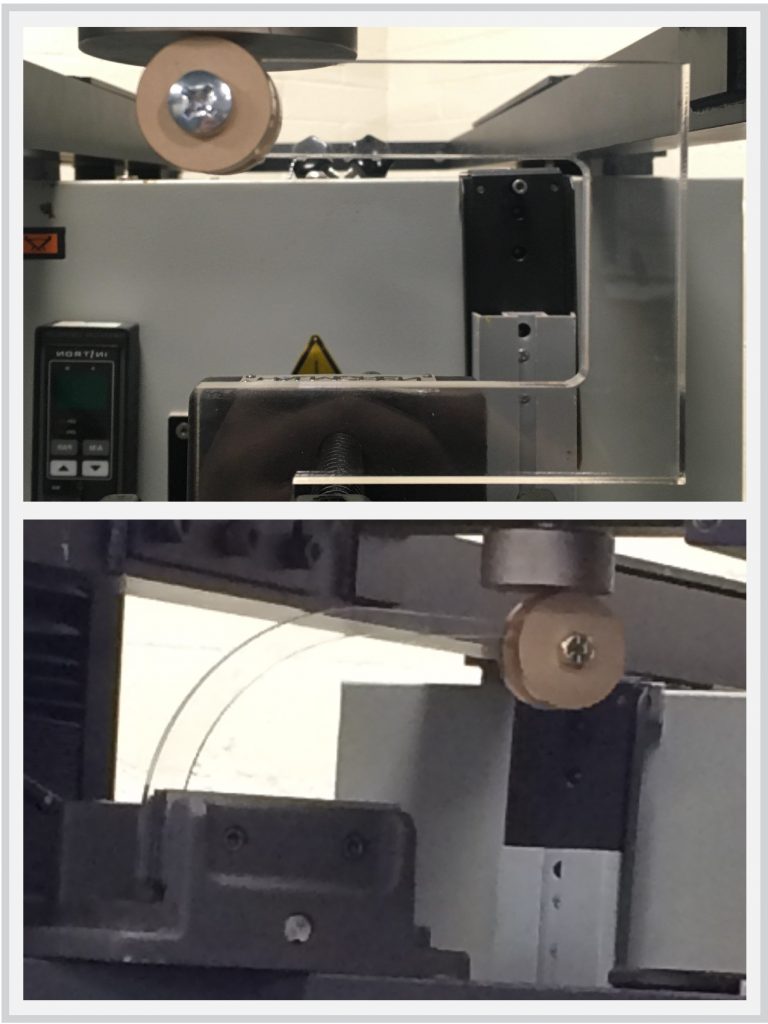

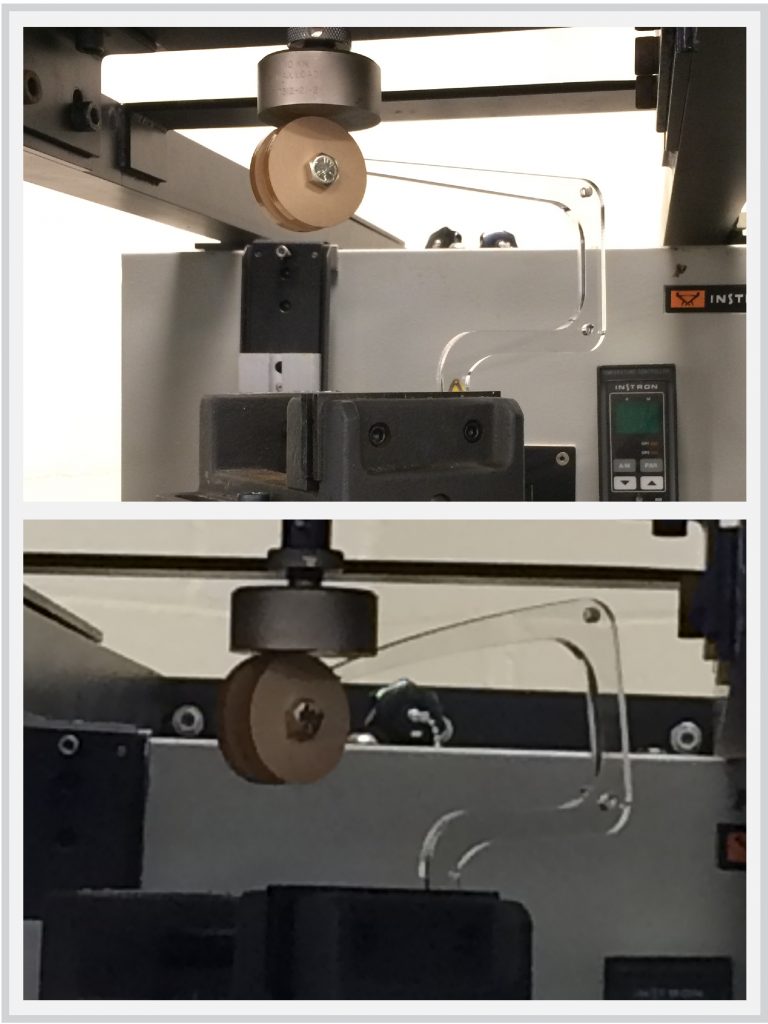

For Fall semester 2017, ME: 042 students were tasked with prototyping and testing an ankle joint design that would allow for the most deflection without failure. To test their designs, students used Bray Lab’s Instron 5800R tensile and compression testing machine. It was fascinating to see some unexpected results from some unusual structures!

Author: khalle03

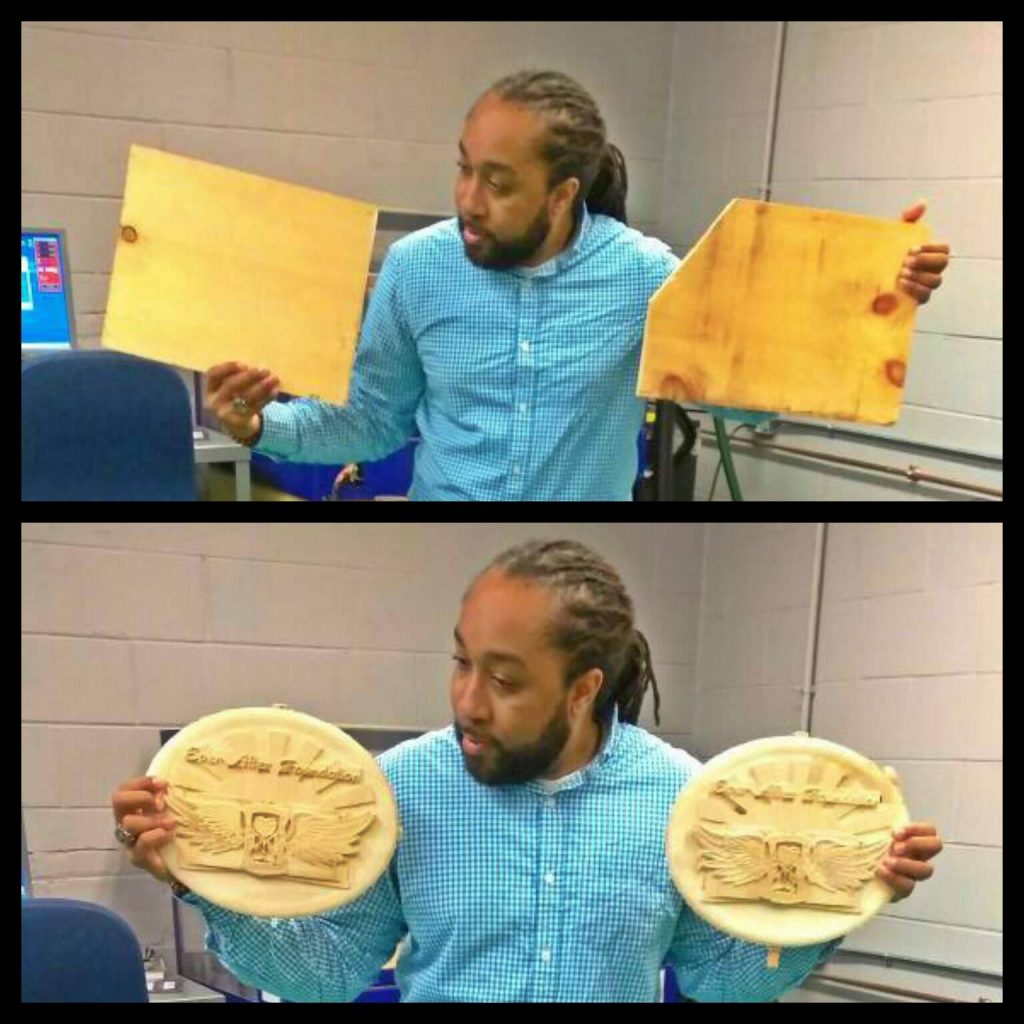

Last Fall semester, Bray assisted staff member David Pierre-Louis with using the CNC Mill for a community project. David is a Financial Services Specialist here at Tufts, and he has a vision for creating a community reading program. To this end, he has crafted an outdoor bookshelf out of recycled wood materials that will live in a local park near his home in Massachusetts. The bookshelf will feature books targeted for both adults and children. David requested the use of the CNC Mill to carve out two emblems for his bookshelf which features the name of his community program: Ever After Foundation.

First, the emblems were prototyped using foam before they were eventually milled out of recycled pine boards.

David with before and after elements of the process.

Bray staff who assisted in the process, pictured left to right: Marya, Kim, and Ben with the CNC mill in the background.

One of the finished emblems before being stained.

Thank you for collaborating with us, David!

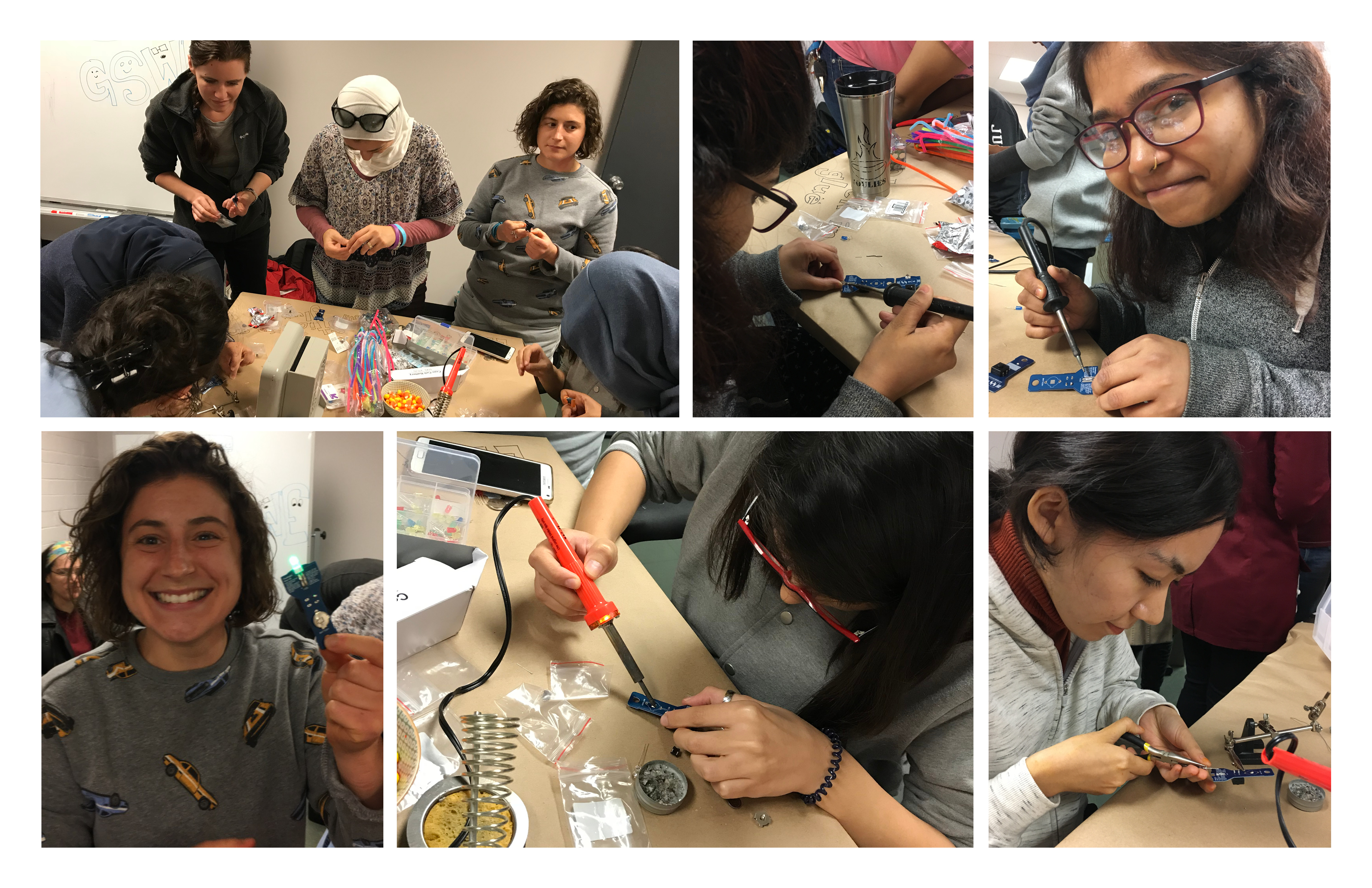

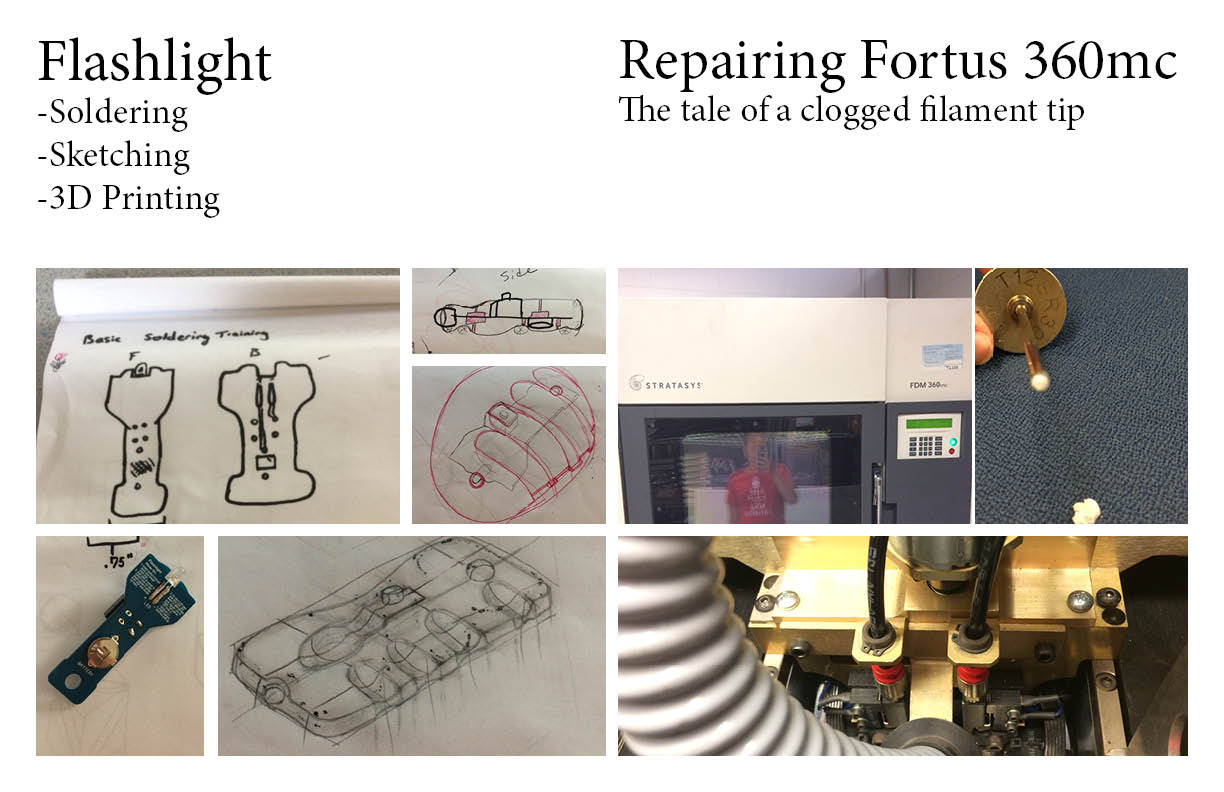

On Thursday, October 26th, the 2nd annual pumpkin carving social for the Graduate Society of Women Engineers (GSWE) was hosted in Bray’s Design Lab. In addition to carving pumpkins, the ladies utilized Bray’s flashlight soldering kits and additional LEDs attached to coin button cell batteries to jazz up their pumpkins engineering-style!

© 2025 Bray Lab

Theme by Anders Noren — Up ↑